The Precision Difference

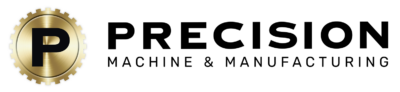

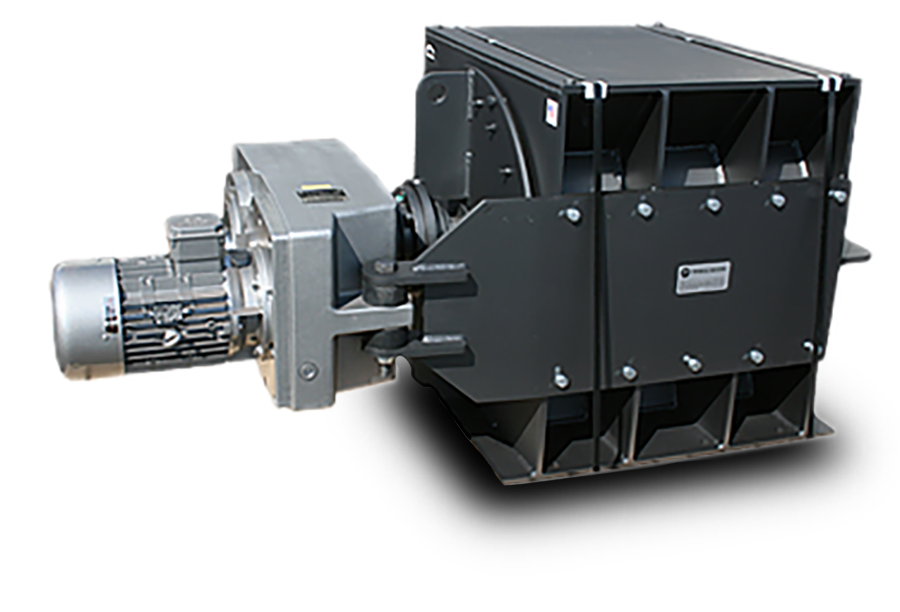

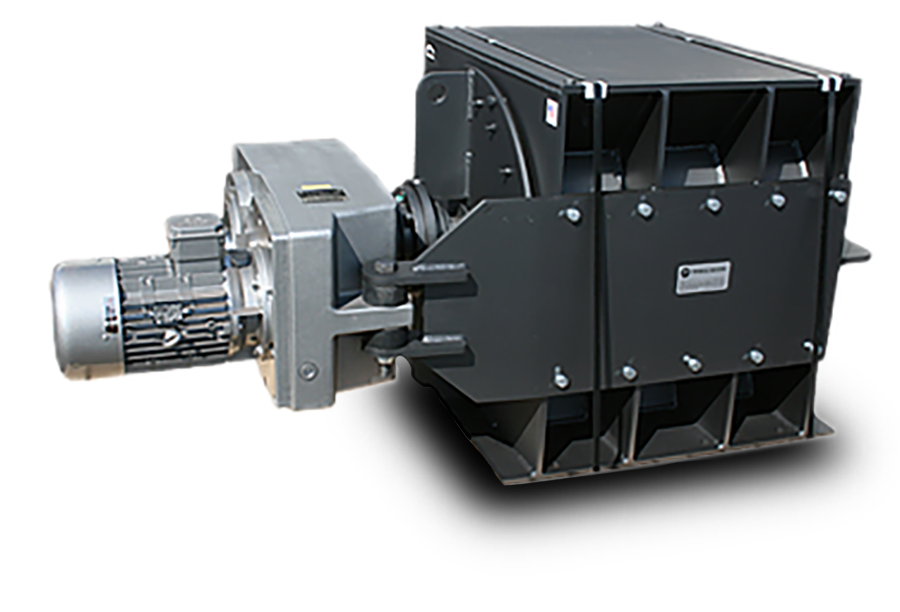

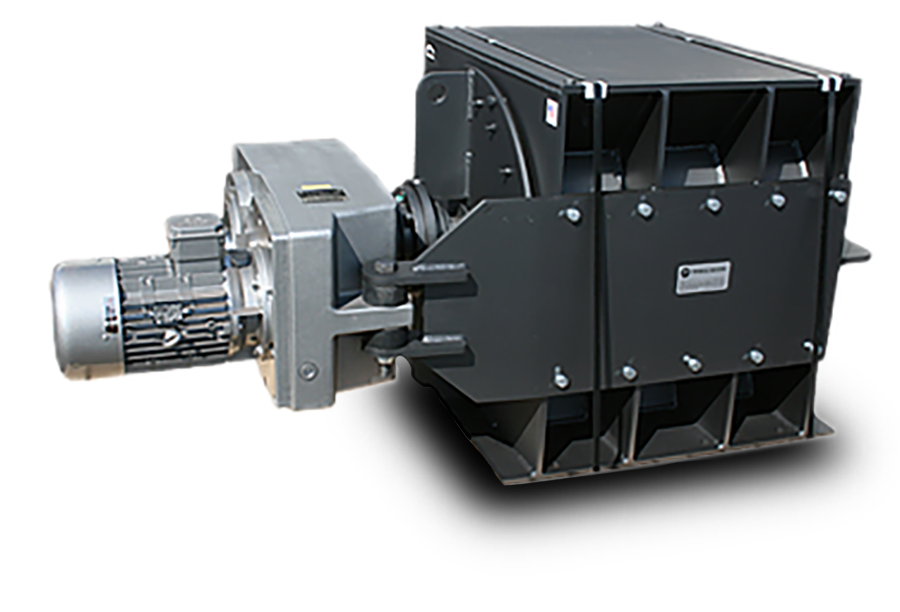

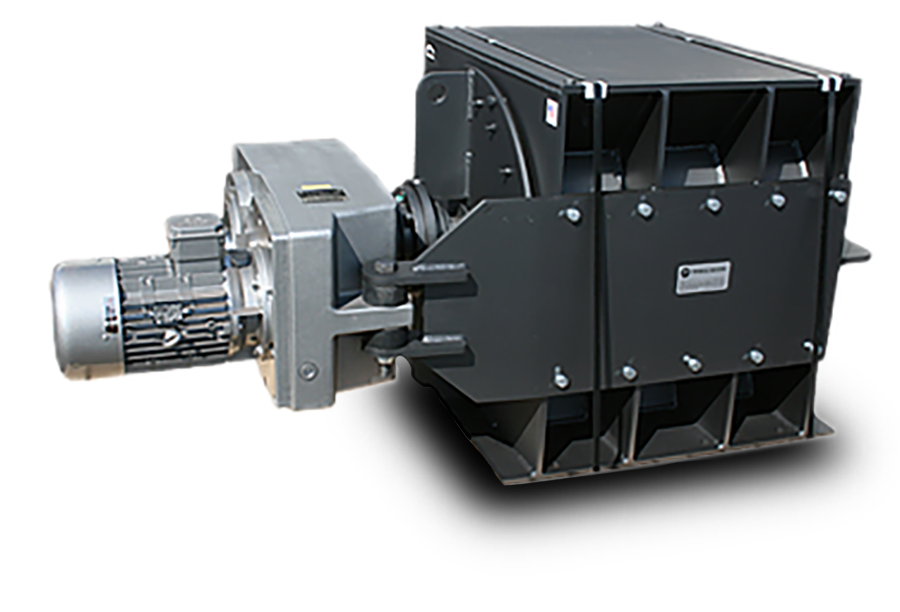

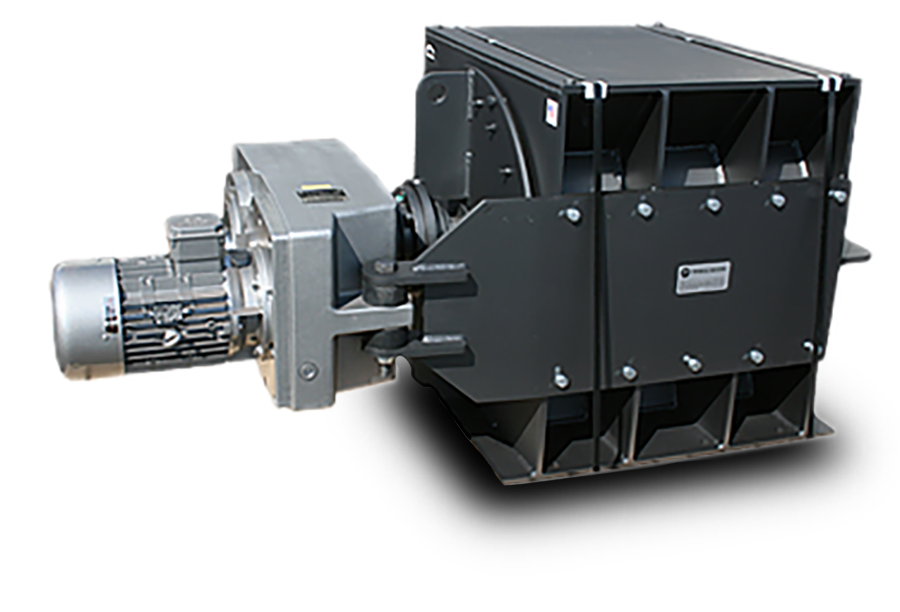

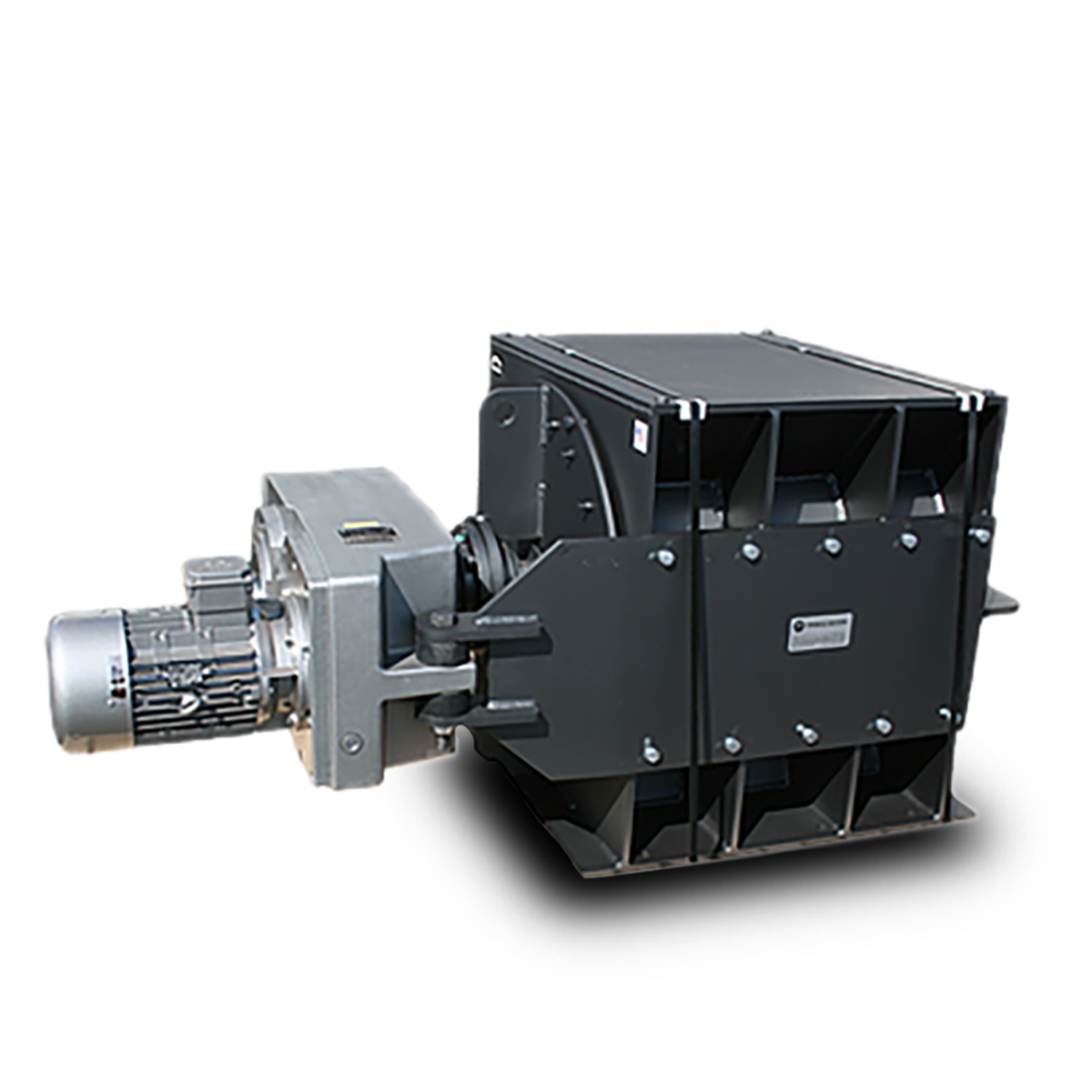

Manufacturing the Heaviest Duty Rotary Feeder Airlocks, Screw Conveyors & Rotary Valve Airlocks in the Material Handling Industry!

Whether you’re moving coal, alternative fuels, dust collection, silo discharge, kiln feed, or other high-volume, high-abrasion raw materials, Precision equipment will keep it moving, consistently, easily and without constant operator intervention. No more need to worry about material flow or assigning employees to fix clogs and spills.

Feeders and valves that fail unexpectedly and cause unplanned downtime cost you production and profitability. With Precision Predictable Performance, feeders and valves last for their rated life. Address routine maintenance and rebuilding on your schedule.

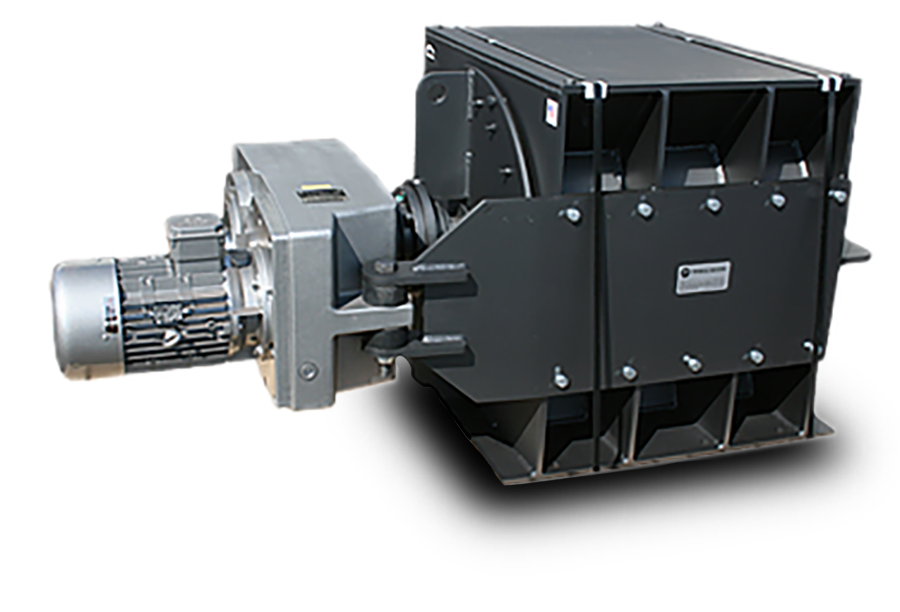

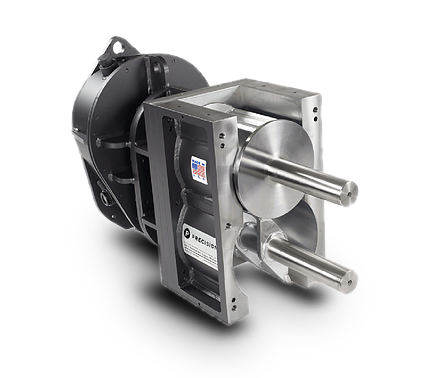

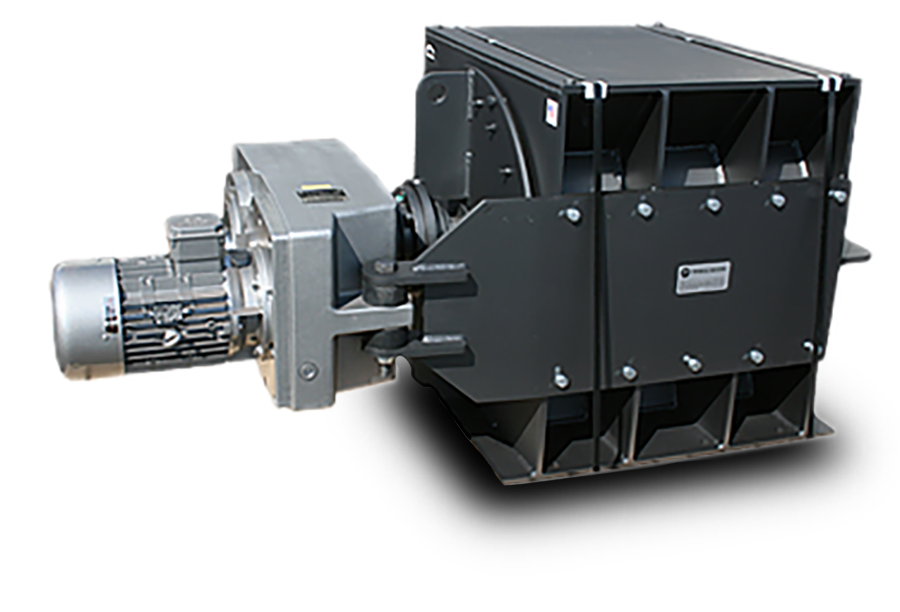

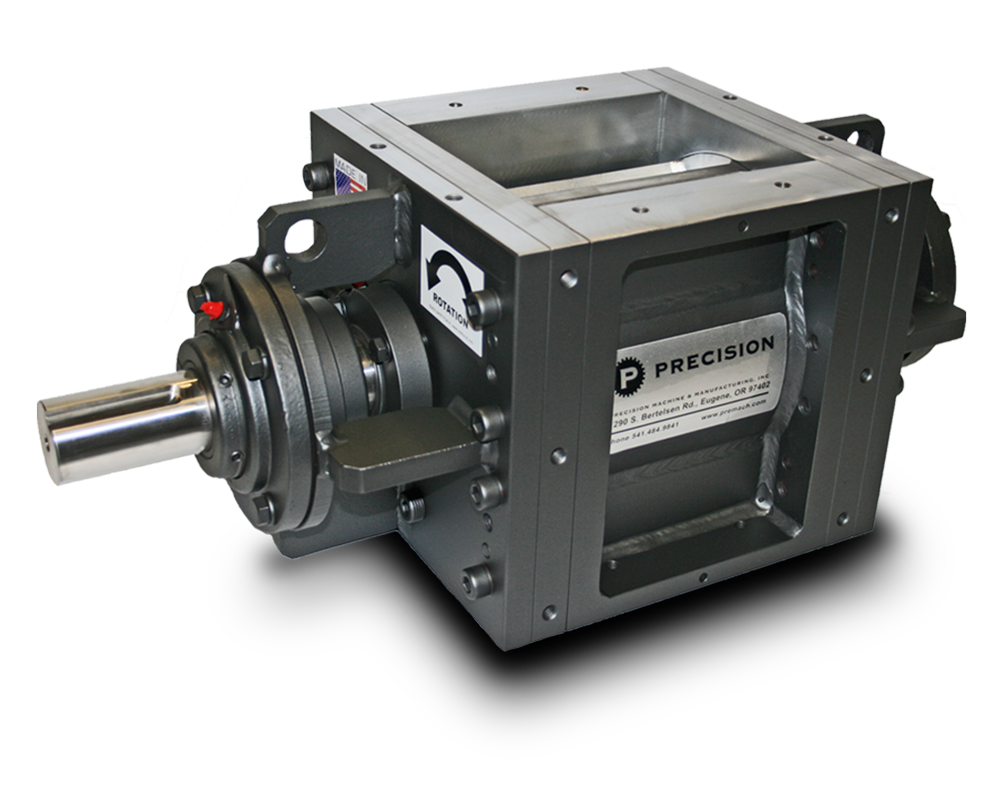

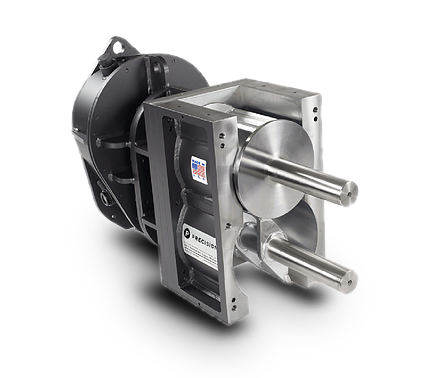

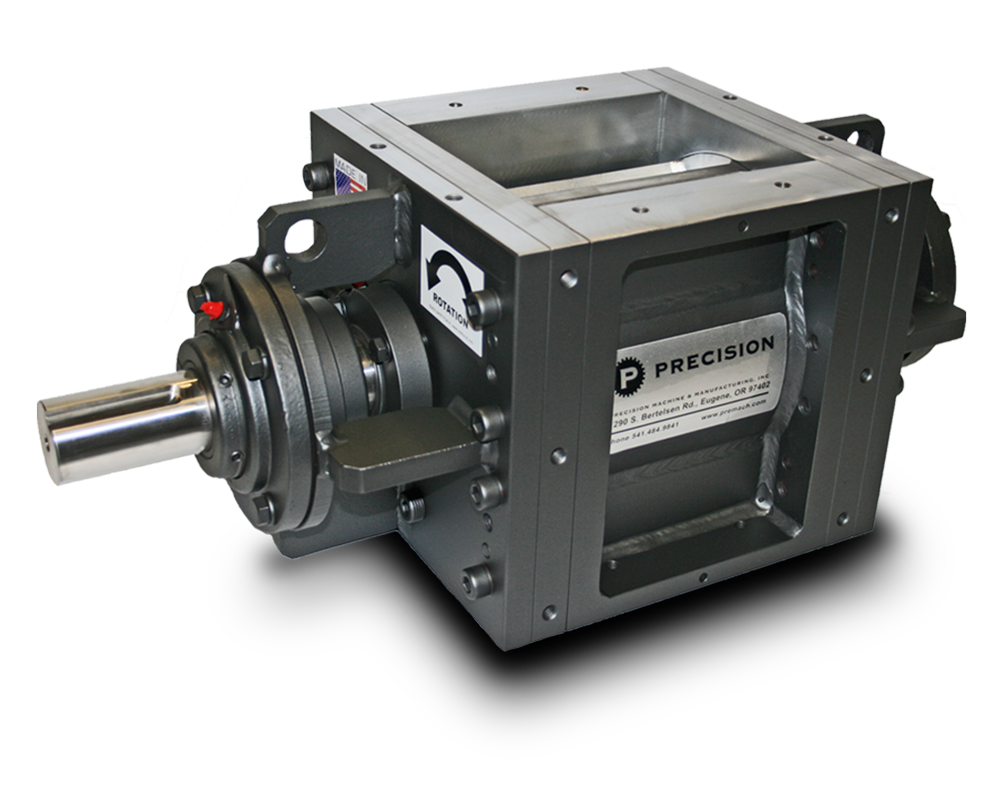

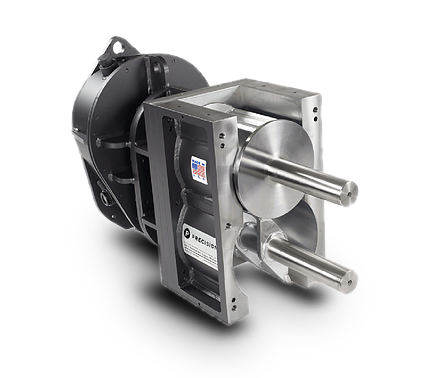

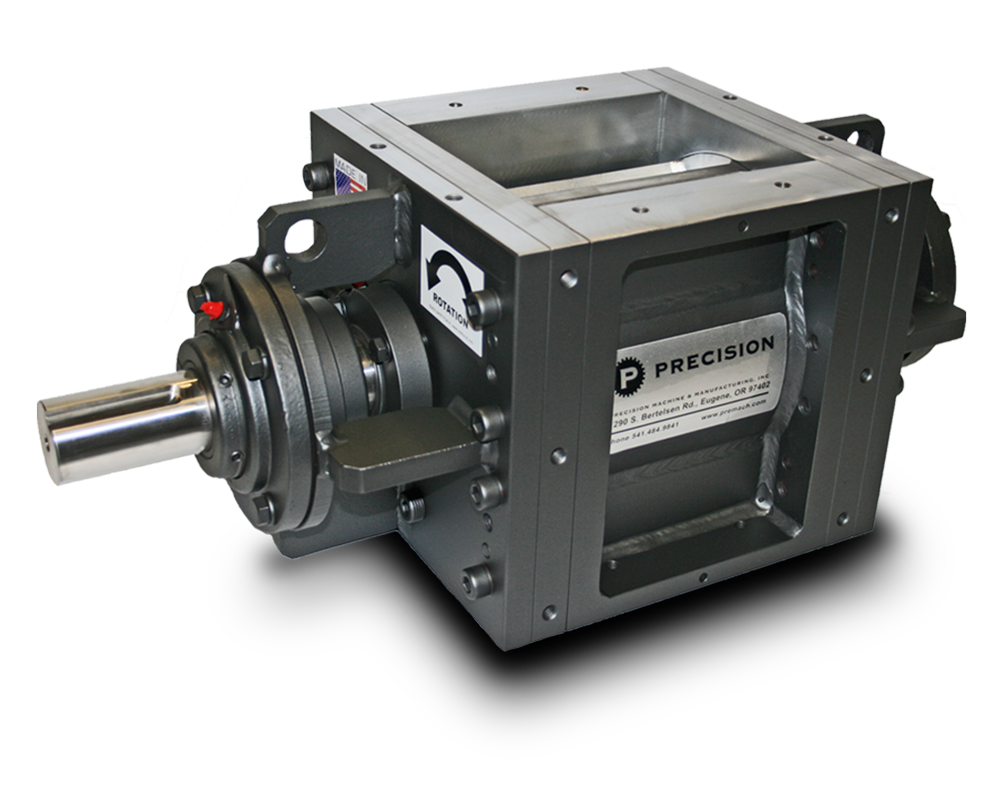

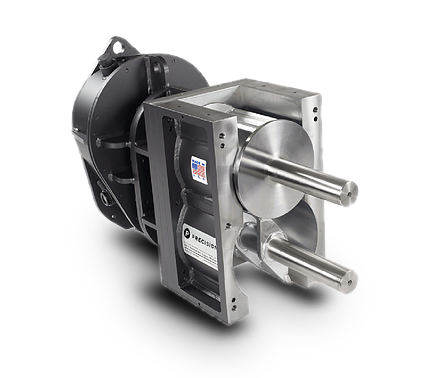

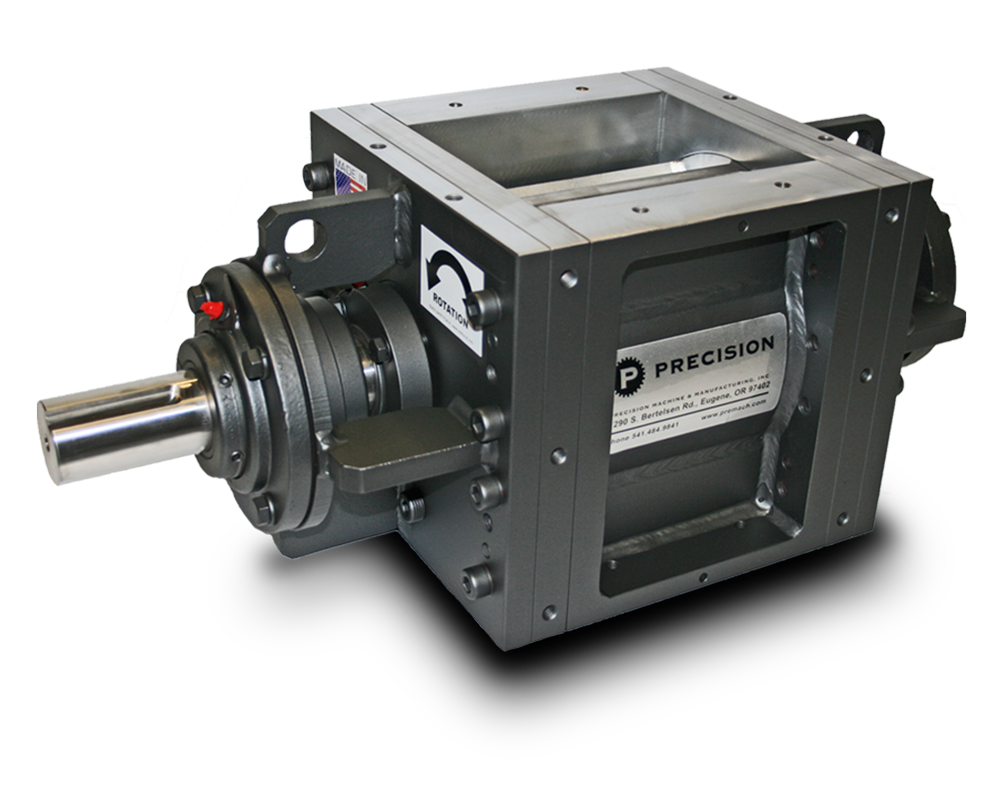

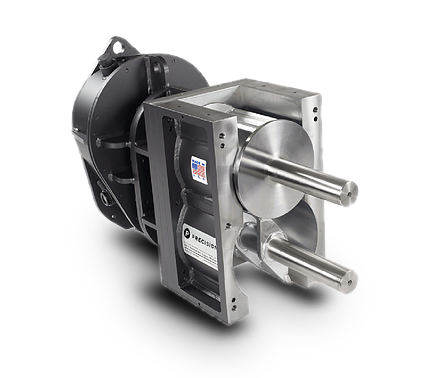

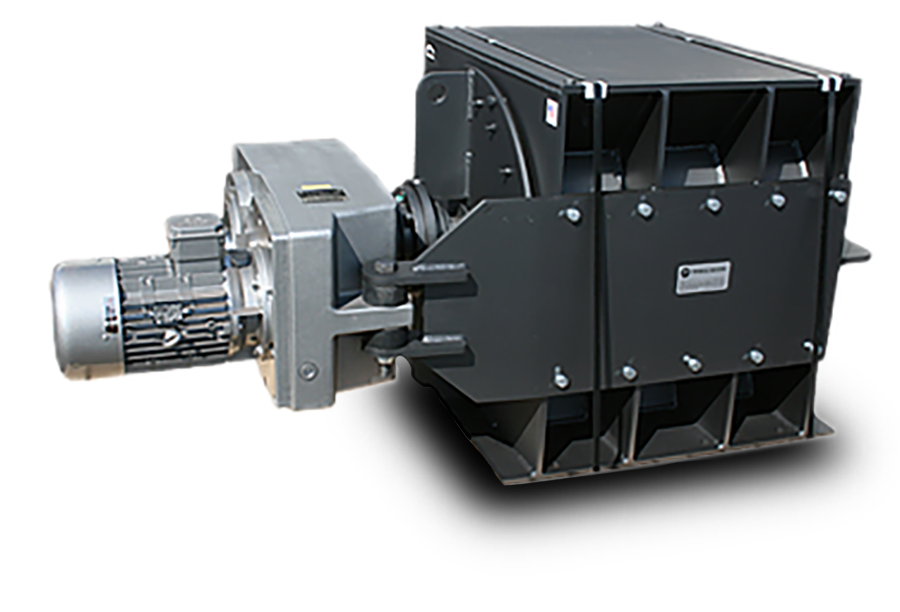

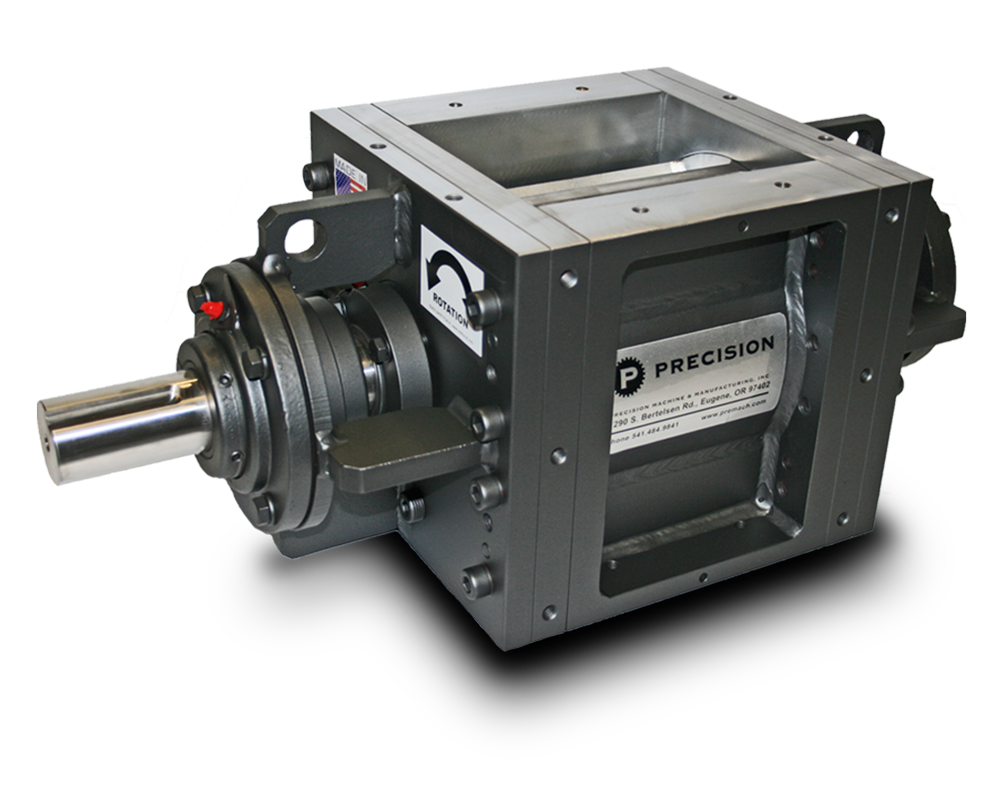

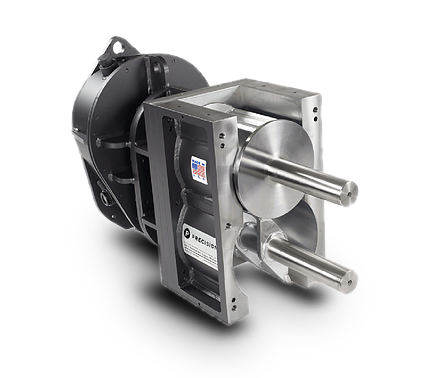

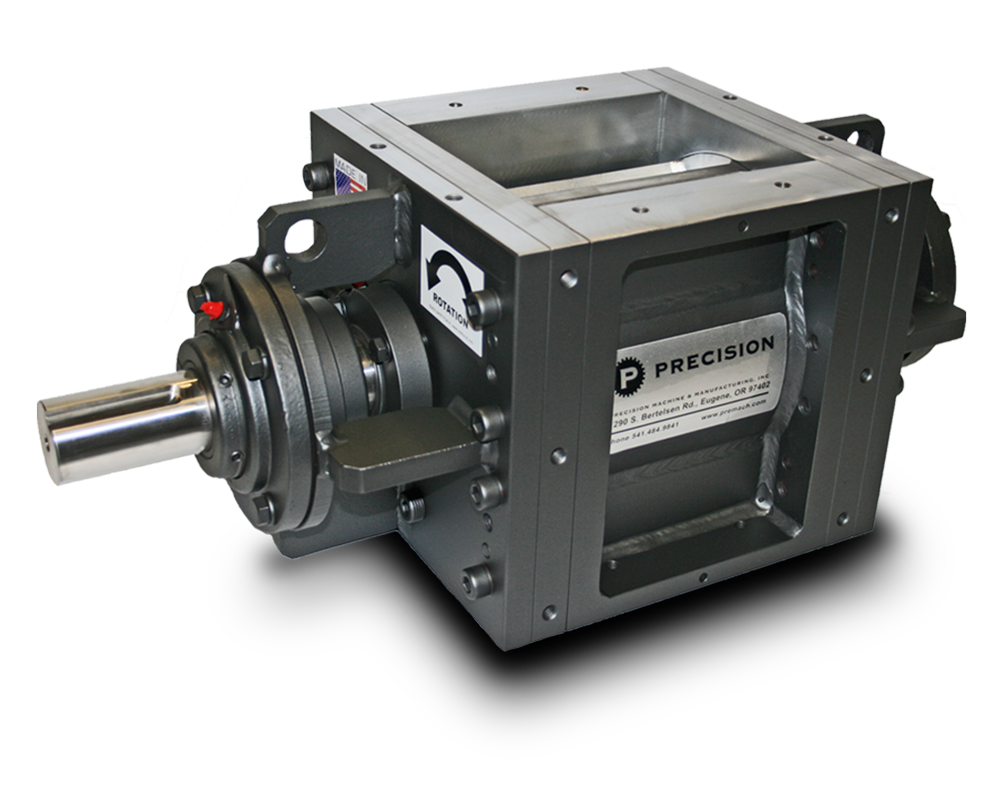

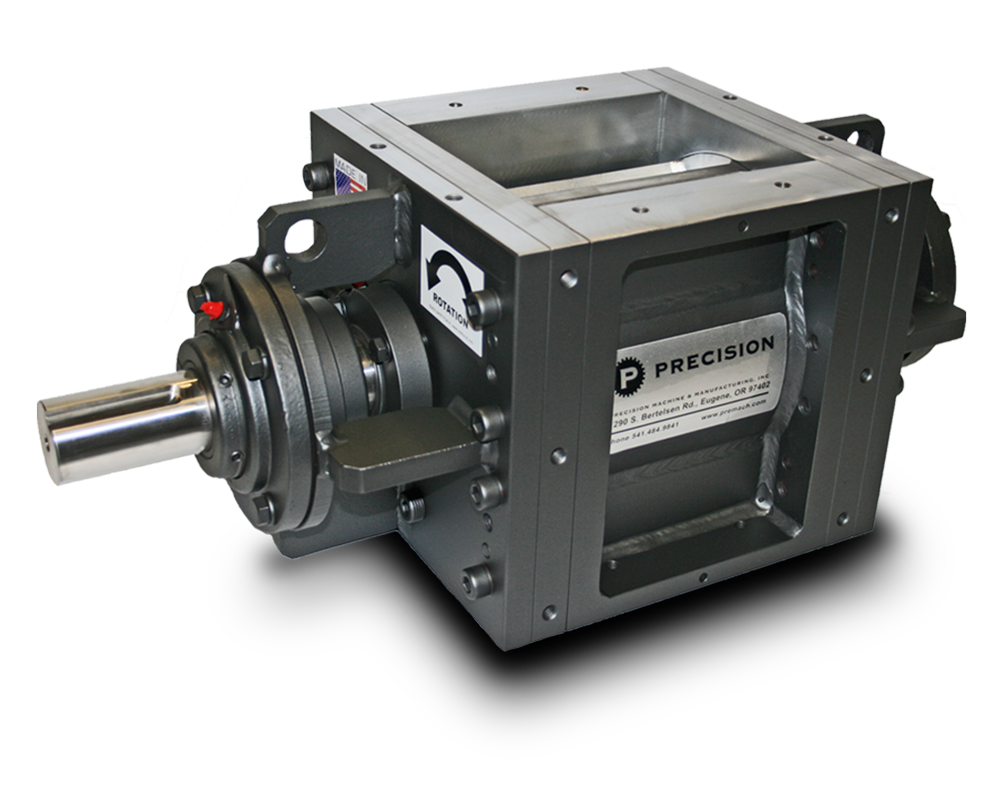

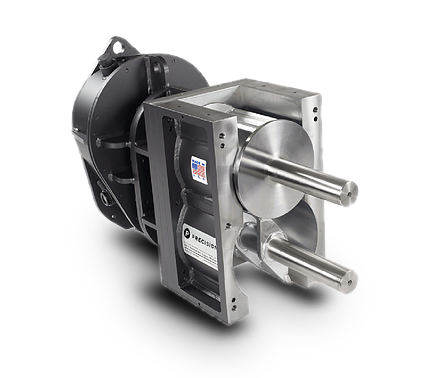

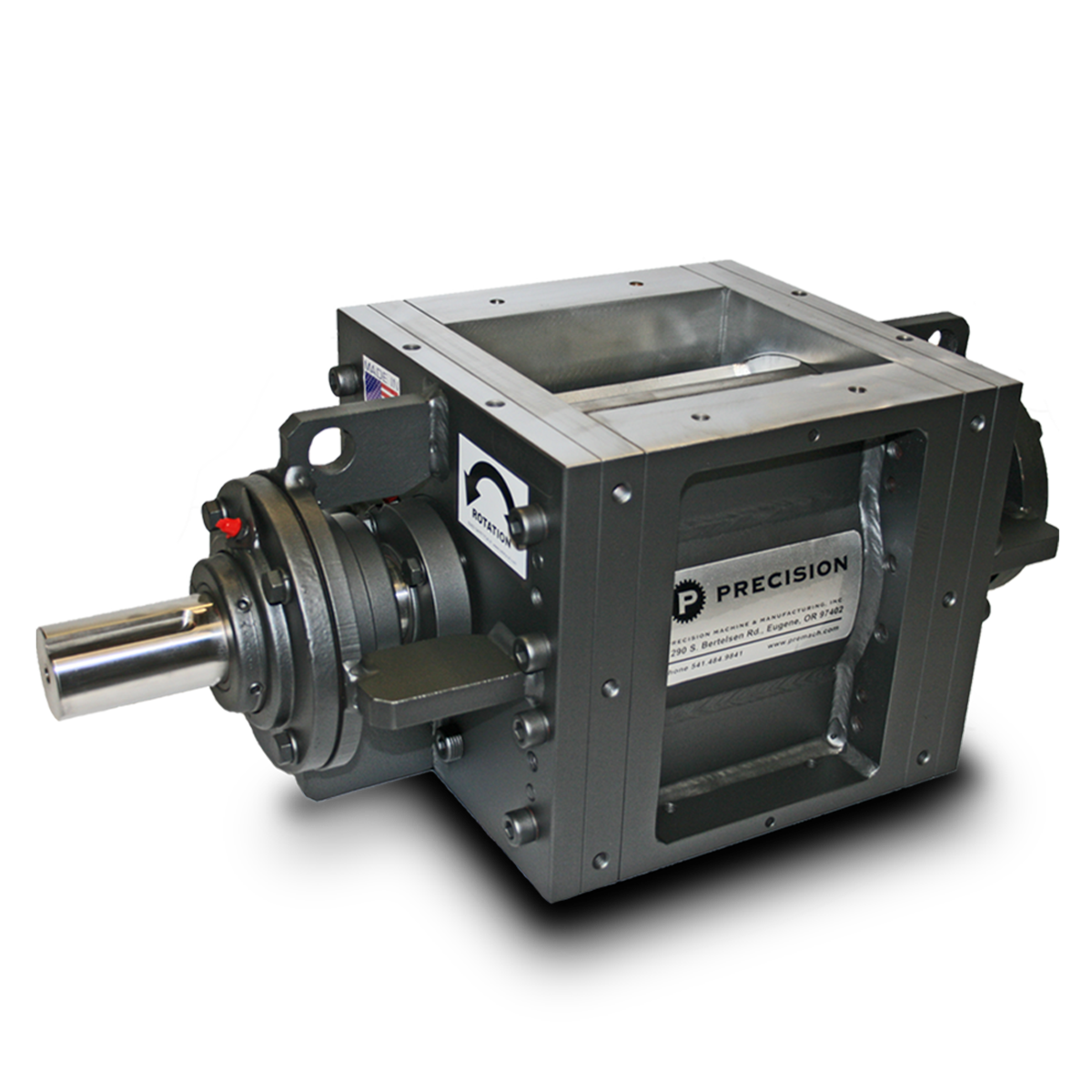

Self-Cleaning Rotary Valve

A mechanically self-cleaning rotary valve for applications where sticky or wet material can build-up in a conventional rotary valve or rotary feeder and disrupt feeding.

Whether you’re moving coal, alternative fuels, dust collection, silo discharge, kiln feed, or other high-volume, high-abrasion raw materials, Precision equipment will keep it moving, consistently, easily and without constant operator intervention. No more need to worry about material flow or assigning employees to fix clogs and spills.

Feeders and valves that fail unexpectedly and cause unplanned downtime cost you production and profitability. With Precision Predictable Performance, feeders and valves last for their rated life. Address routine maintenance and rebuilding on your schedule.

Self-Cleaning Rotary Valve

A mechanically self-cleaning rotary valve for applications where sticky or wet material can build-up in a conventional rotary valve or rotary feeder and disrupt feeding.

Whether you’re moving coal, alternative fuels, dust collection, silo discharge, kiln feed, or other high-volume, high-abrasion raw materials, Precision equipment will keep it moving, consistently, easily and without constant operator intervention. No more need to worry about material flow or assigning employees to fix clogs and spills.

Feeders and valves that fail unexpectedly and cause unplanned downtime cost you production and profitability. With Precision Predictable Performance, feeders and valves last for their rated life. Address routine maintenance and rebuilding on your schedule.

Self-Cleaning Rotary Valve

A mechanically self-cleaning rotary valve for applications where sticky or wet material can build-up in a conventional rotary valve or rotary feeder and disrupt feeding.

Whether you’re moving coal, alternative fuels, dust collection, silo discharge, kiln feed, or other high-volume, high-abrasion raw materials, Precision equipment will keep it moving, consistently, easily and without constant operator intervention. No more need to worry about material flow or assigning employees to fix clogs and spills.

Feeders and valves that fail unexpectedly and cause unplanned downtime cost you production and profitability. With Precision Predictable Performance, feeders and valves last for their rated life. Address routine maintenance and rebuilding on your schedule.

Self-Cleaning Rotary Valve

A mechanically self-cleaning rotary valve for applications where sticky or wet material can build-up in a conventional rotary valve or rotary feeder and disrupt feeding.

Whether you’re moving coal, alternative fuels, dust collection, silo discharge, kiln feed, or other high-volume, high-abrasion raw materials, Precision equipment will keep it moving, consistently, easily and without constant operator intervention. No more need to worry about material flow or assigning employees to fix clogs and spills.

Feeders and valves that fail unexpectedly and cause unplanned downtime cost you production and profitability. With Precision Predictable Performance, feeders and valves last for their rated life. Address routine maintenance and rebuilding on your schedule.

Self-Cleaning Rotary Valve

A mechanically self-cleaning rotary valve for applications where sticky or wet material can build-up in a conventional rotary valve or rotary feeder and disrupt feeding.

Whether you’re moving coal, alternative fuels, dust collection, silo discharge, kiln feed, or other high-volume, high-abrasion raw materials, Precision equipment will keep it moving, consistently, easily and without constant operator intervention. No more need to worry about material flow or assigning employees to fix clogs and spills.

Feeders and valves that fail unexpectedly and cause unplanned downtime cost you production and profitability. With Precision Predictable Performance, feeders and valves last for their rated life. Address routine maintenance and rebuilding on your schedule.

Self-Cleaning Rotary Valve

A mechanically self-cleaning rotary valve for applications where sticky or wet material can build-up in a conventional rotary valve or rotary feeder and disrupt feeding.

Whether you’re moving coal, alternative fuels, dust collection, silo discharge, kiln feed, or other high-volume, high-abrasion raw materials, Precision equipment will keep it moving, consistently, easily and without constant operator intervention. No more need to worry about material flow or assigning employees to fix clogs and spills.

Feeders and valves that fail unexpectedly and cause unplanned downtime cost you production and profitability. With Precision Predictable Performance, feeders and valves last for their rated life. Address routine maintenance and rebuilding on your schedule.

Self-Cleaning Rotary Valve

A mechanically self-cleaning rotary valve for applications where sticky or wet material can build-up in a conventional rotary valve or rotary feeder and disrupt feeding.

Whether you’re moving coal, alternative fuels, dust collection, silo discharge, kiln feed, or other high-volume, high-abrasion raw materials, Precision equipment will keep it moving, consistently, easily and without constant operator intervention. No more need to worry about material flow or assigning employees to fix clogs and spills.

Feeders and valves that fail unexpectedly and cause unplanned downtime cost you production and profitability. With Precision Predictable Performance, feeders and valves last for their rated life. Address routine maintenance and rebuilding on your schedule.

Self-Cleaning Rotary Valve

A mechanically self-cleaning rotary valve for applications where sticky or wet material can build-up in a conventional rotary valve or rotary feeder and disrupt feeding.

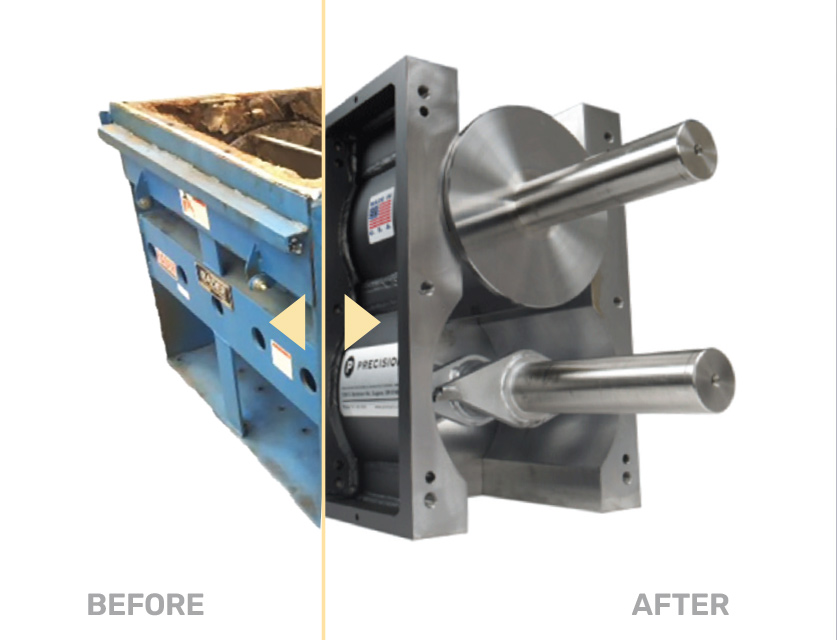

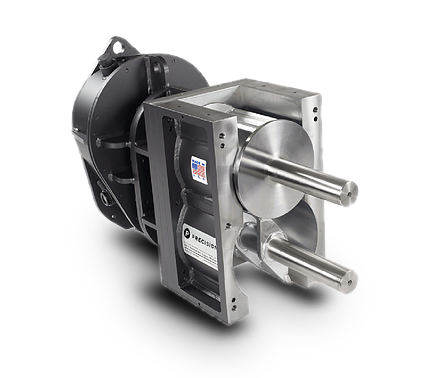

HEAVY-DUTYLONG-LASTINGREBUILDABLE AIRLOCKS

100% Made in the United States of America!

At PMM, we pride ourselves on manufacturing the most functional and durable Rotary Airlock Feeders, Screw Conveyors, and Rotary Valve Airlocks in the industry and right here in the United States of America.

From our perspective, the rest of the industry is simply fighting for second place!

The Precision Difference is choosing “Quality” and “American Made!”

|

Traditional Cast-Iron Rotary Valve |

VS. |

PMM’s Heavy Duty Rotary Valve |

||

|---|---|---|---|---|---|

|

|

||||

| Performance | |||||

Performance |

Cast-Iron manufacturing process does not allow for the tightest possible rotor to housing clearances resulting in faster wear rates, increased maintenance, and reduced throughput due to greater “blow-By.” | The proprietary manufacturing process centers around producing the tightest possible clearances, which minimizes “blow-by” and maximizes throughput. | |||

| Durability | |||||

Durability |

Cast-Iron harness ranges between 250-350 Brinell, which results in much faster wear rates, significantly reduced throughput, increased maintenance, and more frequent replacements. | Manufactured from a specialty formulated, through-hardened, abrasion-resistant steel alloy with a hardness rating of 500 Brinell/50 Rockwell, and is surface treated increasing the overall hardness to near 600 Brinell/60 Rockwell. This results in much slower wear rates, far more throughput, decreased maintenance, and a longer-lasting rotary valve. | |||

| Operational Temp. | |||||

Operational Temp. |

Standard operating temperatures for cast-iron is limited to between 300-500 degrees Fahrenheit. | Configurable to operate at temperatures between 1,000-1,200 degrees Fahrenheit. | |||

| Maintenance | |||||

Maintenance |

Difficult to maintain due to being constructed of a single casting, resulting in total replacement of the valve if wear is identified in a single area. Lighter-duty bearings cause shaft misalignment and difficult access. Furthermore, material blockages are commonplace. | Minimal maintenance required! The Modular design allows for quick onsite wear item replacement resulting in very little downtime. Heavy-duty outboard roller bearings keep the rotor shaft perfectly aligned eliminating binding caused by misalignment. Minimal air blow-by keeps material blockages to a minimum. Rebuild versus replace! | |||

| Price | |||||

Price |

Comparatively, the sales price of a standard cast iron feeder can be significantly less, which is due to the inexpensive casting process, and the inherent light-duty construction. Unfortunately, the low initial purchase price is quickly surpassed as these units require more frequent replacements due to increased wear rates. | Overall Cost ROI (Return on Investment): While the initial sales price may come in a bit higher, the longer service life, reduced maintenance costs, and less downtime result in a more favorable cost ROI over the entire lifespan of the product. This results in the rotary valve offering a much greater value for the money spent when considering the total costs over time. | |||

Why Precision?