Rotary Airlocks & Screw Conveyors designed for the demands of Biomass Power & Cogeneration Systems

Biomass power generation facilities handle some of the most challenging materials in power plant service, including hog fuel, wood waste, pellets, alternative biomass fuels, carbon, rubber, biomass ash to name a few. These materials vary widely in size, density, and flow characteristics, ranging from abrasive and powdery to fibrous, irregular, and clumpy, creating constant risk for material buildup, flow restriction, false air infiltration, and premature equipment wear. In biomass boiler feed and ash handling systems, these failures lead directly to downtime, reduced efficiency, and increased maintenance costs.

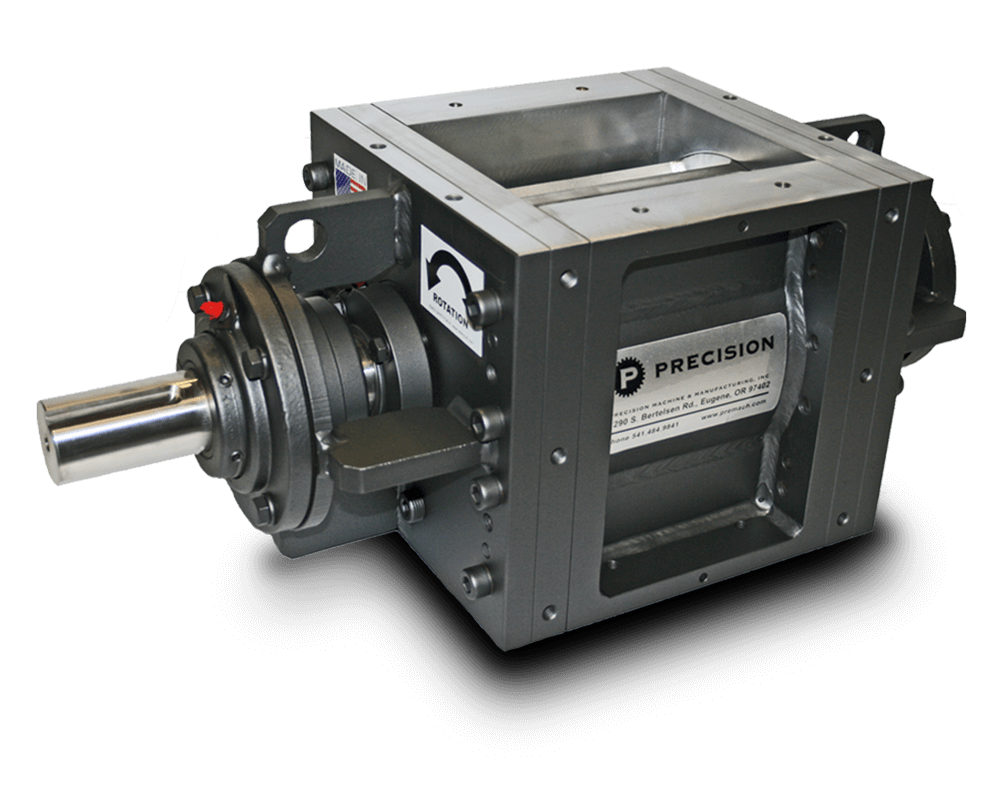

Precision Machine & Manufacturing (PMM) manufacturers heavy-duty rotary airlocks and screw conveyors engineered specifically for biomass power generation and cogeneration applications, delivering reliable performance under extreme abrasion, high temperatures, and continuous-duty operations, while supporting drop-in replacement and retrofit solutions that protect plant uptime.

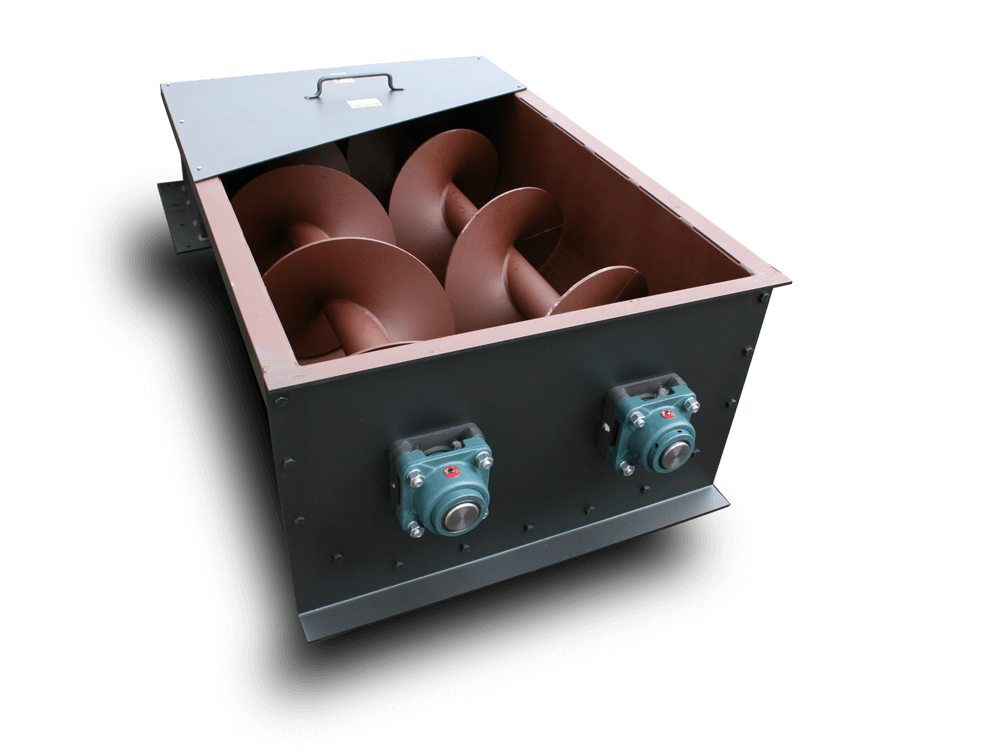

Rotary Airlock Feeder w/ Shear Knife

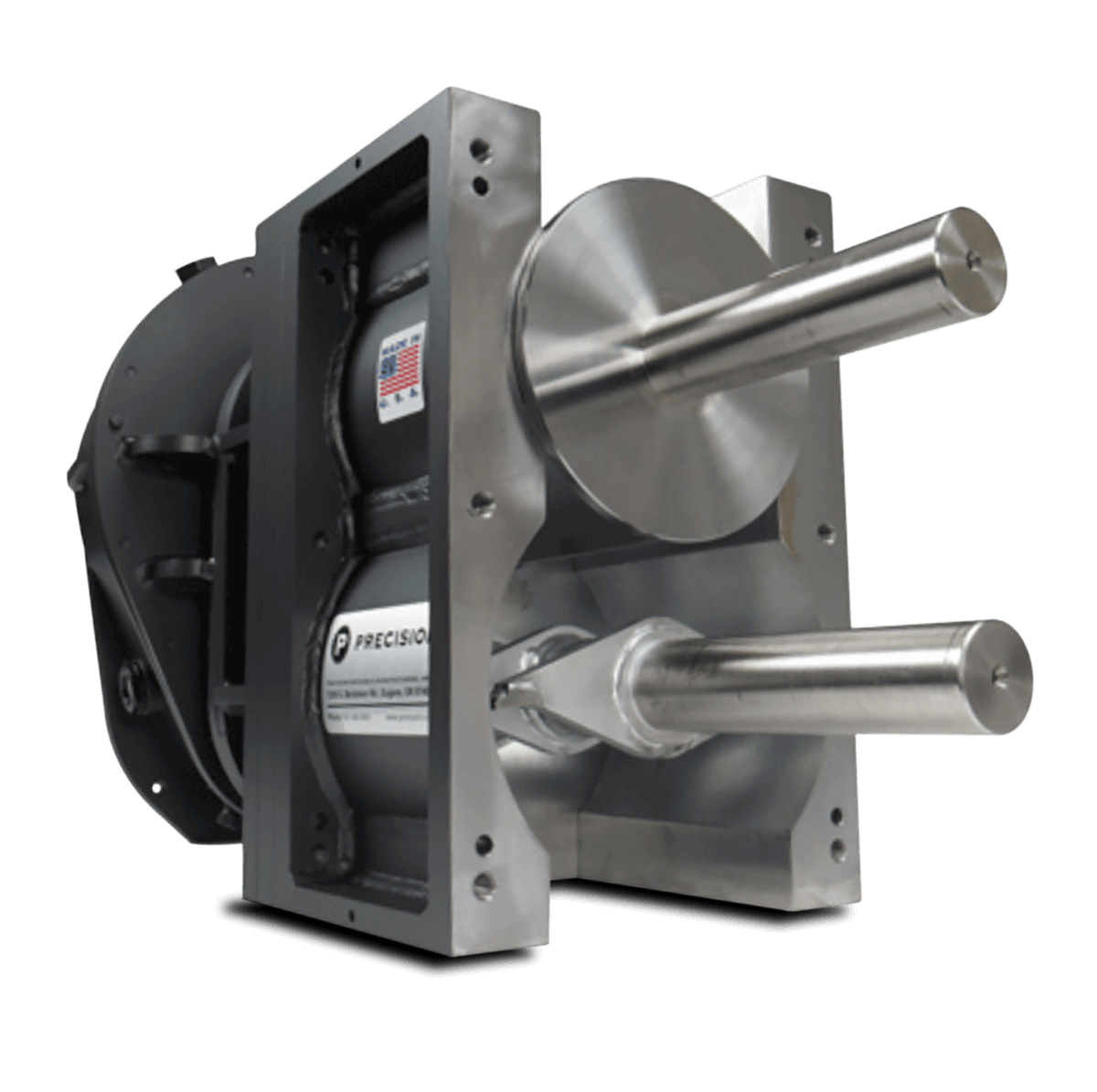

Self-Cleaning Rotary Airlock Valve

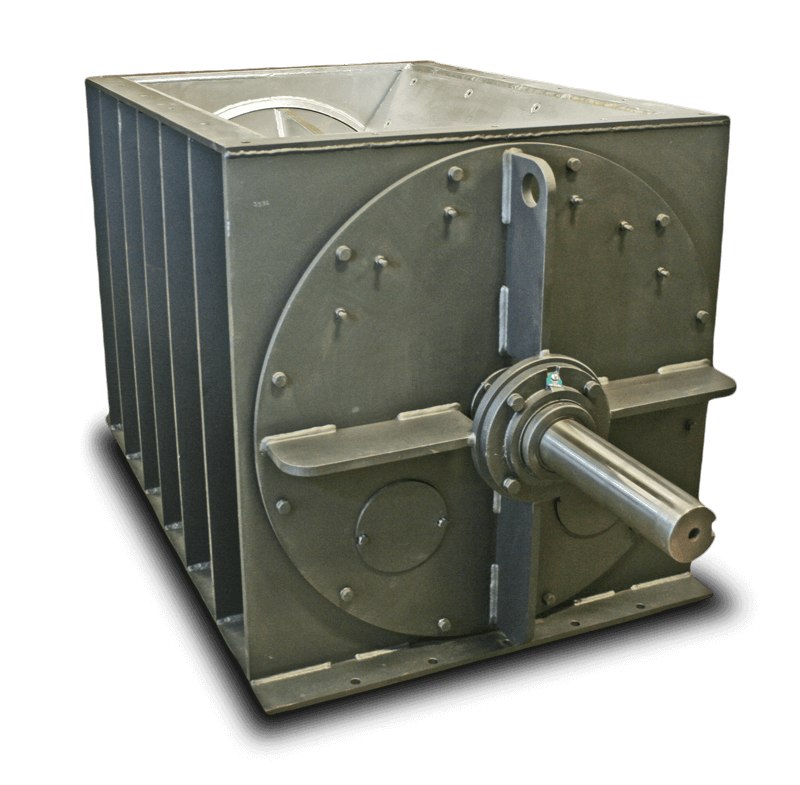

Extremely Robust Rotary Airlock Valve

HD Rotary Airlocks & Screw Conveyors:

Biomass Power Generation Material Handling – FAQ’s