Heavy-Duty Material Handling for Wood Processing Industries | Rotary Airlocks & Screw Conveyors

Wood processing applications handle some of the industry’s most challenging bulk materials, including stringy, dusty, abrasive, irregular, and high-temperature wood byproducts. To prevent clogs, false air, and premature wear in sawmills, panel plants, pellet mills, wood waste, and cogeneration systems, PMM’s heavy-duty rotary airlocks and screw conveyors deliver reliable material handling performance in demanding wood processing environments.

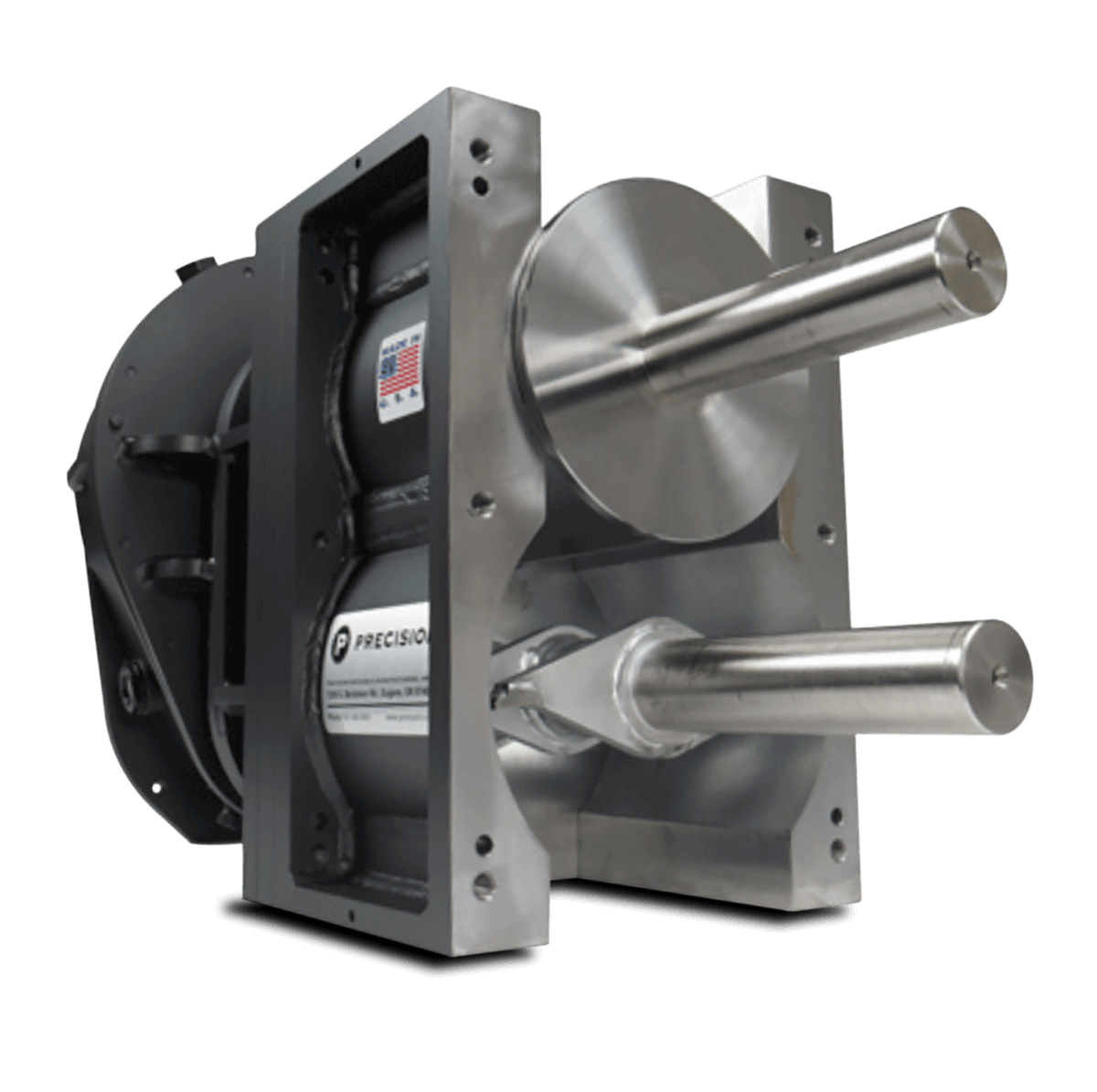

Rotary Airlock Feeder w/ Shear Knife

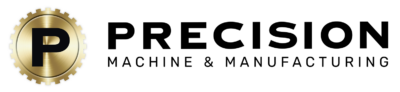

High-Capacity Rotary Airlock Feeder

Dust collection and pneumatic conveying systems.

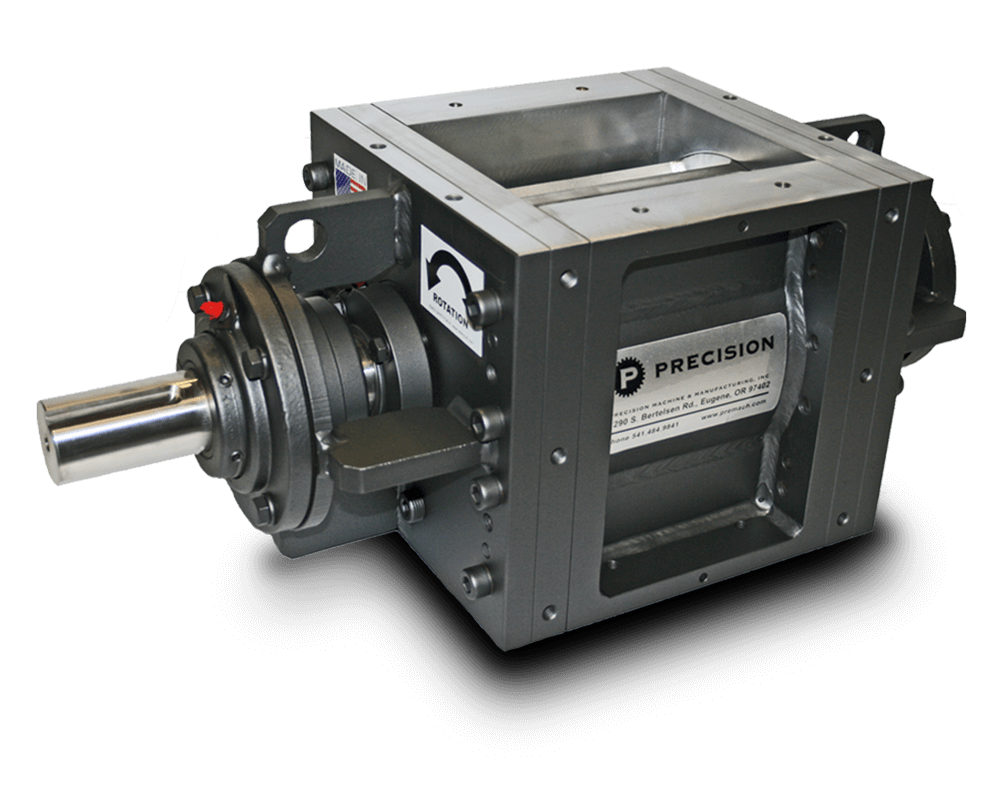

Extremely Robust Rotary Airlock Valve

Side-Entry Rotary Airlock Valve

Pellet Handling, Dust Collection, Baghouse

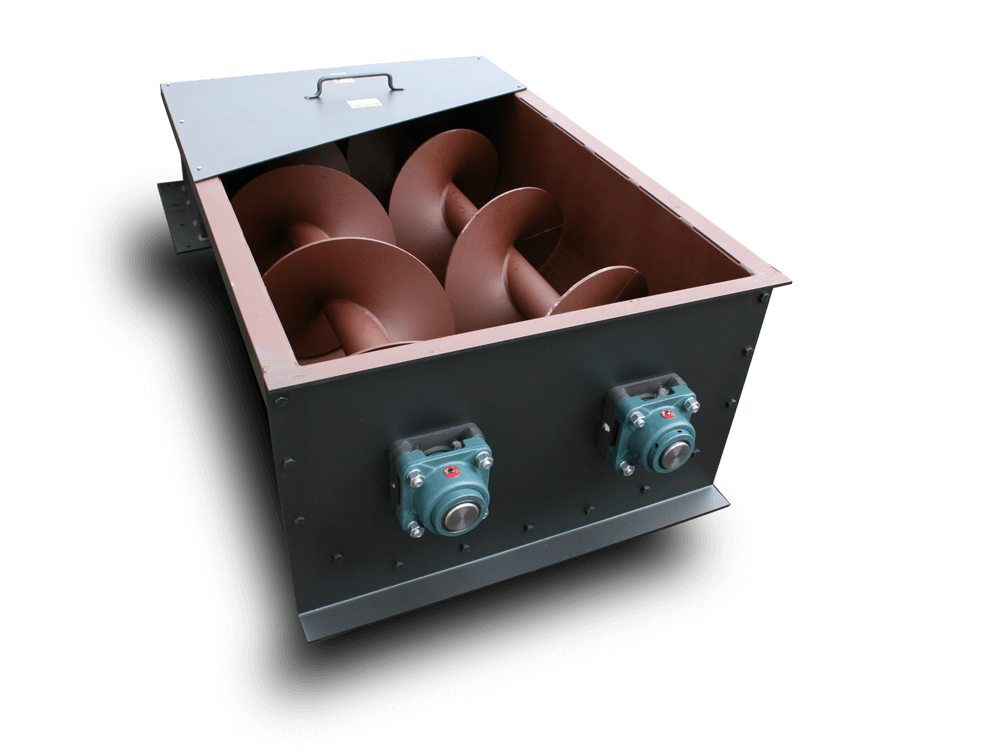

Heavy-Duty Screw Conveyors for Wood Processing

HD Rotary Airlocks & Screw Conveyors:

Wood Manufacturing Bulk Material Handling – FAQ’s