Rotary Valve Airlocks for Plastics Manufacturing and Chemical Processing

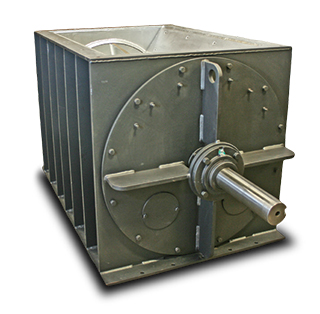

Processing chemicals and manufacturing plastics requires extremely robust and highly functional Airlocks. This is why Precision Machine & Manufacturing designed the ultra-durable Rotary Valve Airlock and is one reason why its popularity has grown so rapidly over the past several years. Manufactured from a specialty formulated U.S. sourced abrasion-resistant steel alloy and precisely engineered to achieve the tightest possible rotor to housing clearances, PMM’s Rotary Valve Airlock is by far the industry’s most durable, longest-lasting, and top-performing Airlock by a wide margin.

Extreme Duty Rotary Valve Airlock

Double Slope Rotary Feeder Airlock

Self-Cleaning Rotary Valve Airlock

Rotary Airlock Feeder w/Knife

CHEMICALS INDUSTRY

Rotary Valve

Airlocks

- Keep critical material handling components moving! Every Rotary Valve Airlock is manufactured with the most durable U.S. sourced materials, and precisely engineered to maximize throughput. Maintenance engineers can spend their time developing efficiencies and not maintaining airlocks.

- PMM Rotary Valve Airlocks promote compliance with environmental regulations! All Rotary Valve Airlocks are manufactured to reduce material loss by minimizing dust creation, which is an important part of any dust collection system.

- Keep material loss to a mininum! All Rotary Airlock Valves are manufactured with the tightest possible tolerances, which keeps material traveling in the intended direction and not back upstream, which is a common problem in cast-iron airlocks due to excessive wear.

- Abrasion-Resistant Components! All Rotary Valve Airlocks are manufactured from a proprietary steel alloy that is through hardened to 500 Brinell and surface treated to 60 Rockwell. There is not a more durable rotary airlock in the material handling industry.

- Feeding high moisture content materials into a dryer or blender? Eliminate sticking and clogging of hard-to-handle materials and maintain superior airlock functionality with PMM's Self-Cleaning Rotary Valve Airlock!

- Single Source Supplier of all your rotary valve airlocks. Simplify spare and critical parts by utilizing PMM as your preferred supplier for material handling components.

- Rebuildable! All PMM Rotary Valve Airlocks are rebuildable! This provides a greater ROI over the life of the product and significantly reduces CAPEX budgets and overall maintenance costs.