Rotary Airlock Feeders for the Agriculture & Ingredient Processing Industries

Whether the material being conveyed is agriculture waste, pet food, and/or feedstock, Precision Machine & Manufacturing has the perfect Rotary Airlock to meet the unique needs of these industries. With a proven track record in raw ingredient processing such as rice and sugar cane, as well as carefully transferring fragile feedstock without crushing it, Precision Machine & Manufacturing specializes in developing material handling solutions that will meet the unique needs of your food processing application.

Made in America!

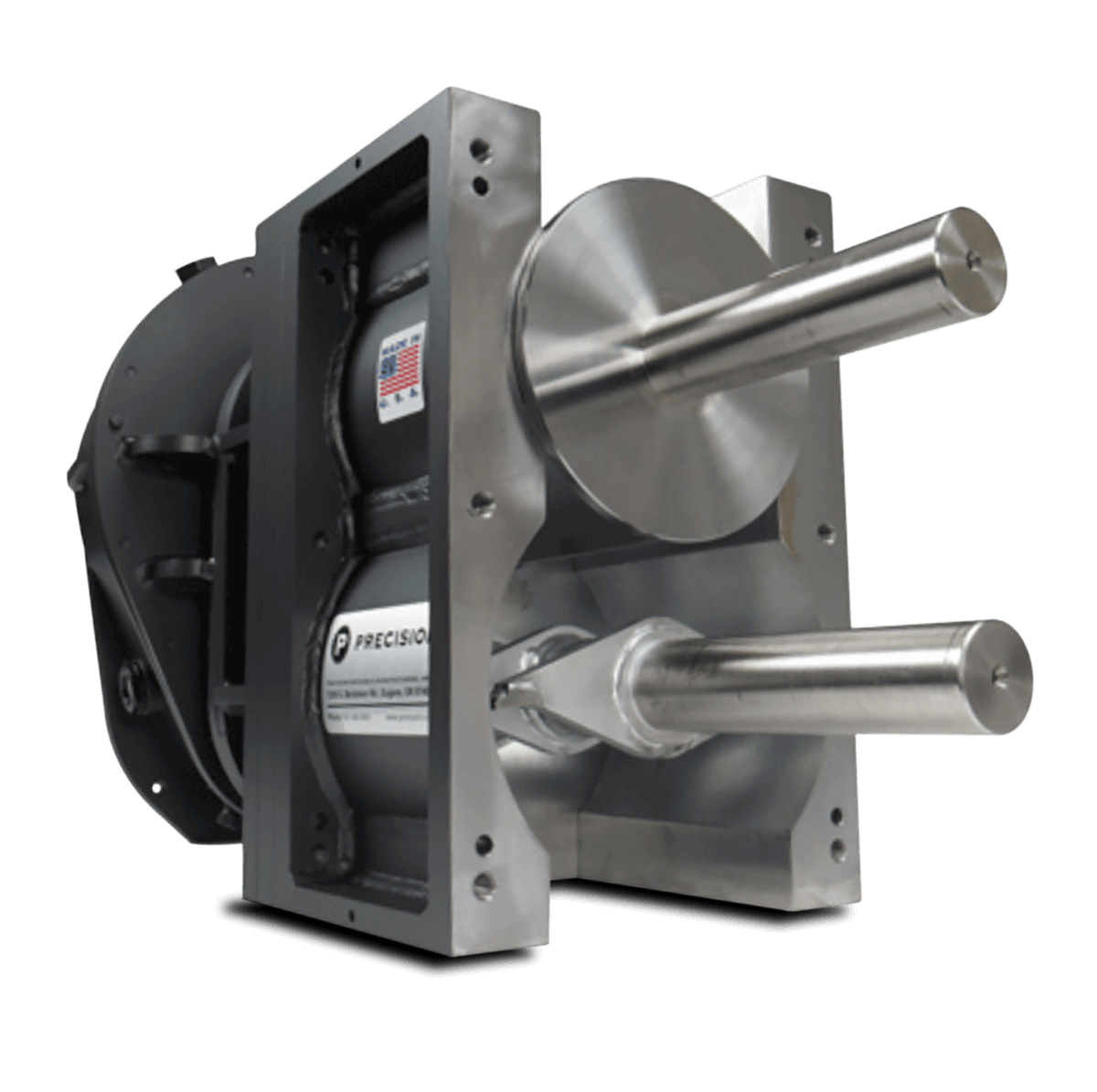

Rotary Feeder Airlock w/Knife

PROCESSING INDUSTRIES

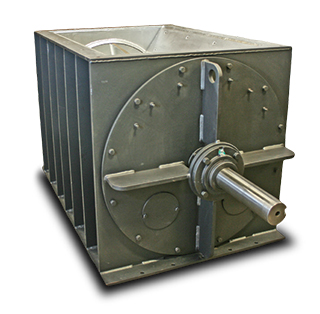

Rotary Airlock Valves & Feeders

- A common rotary feeder doing uncommon things! Not all rotary feeders are created equal! Precision Machine & Manufacturing's Rotary Airlock Feeders are uniquely sized and designed to meet the needs of the application. Equipped with a hardened tool steel knife, which helps to reduce/eliminate clogging issues by shearing irregularly sized materials down to a common size before the material exits into the pneumatic conveying system. The Rotary Airlock Feeder is the perfect addition to any organic material processing system.

- Eliminate constant maintenance headaches. Many "off the shelf" airlocks do not take into consideration the unique aspects of the application and the material being conveyed. PMM takes the time to understand the application while ensuring we provide a solution and not just a product.

- PMM Rotary Airlock Feeders are rebuildable! Most airlocks within the material handling industry are cast-iron, which means they are a one-time use airlock. Very similar to a disposable razor! PMM's Rotary Airlock Feeders are rebuildable, which is very similar to a reusable razor that brings more value the longer its used. When the rebuildable feature is utilized correctly, a nice exchange program is opened up, which significantly reduces CAPEX expendetures and downtime.

- No "One Size Fits All" here at PMM! We closely evaluate every aspect of the application and specify the appropriate airlock and add-on features to meet the unique needs of the material handling application.

- Feeding high moisture content materials into a dryer or blender? In these applications, we have had great success deploying our Self-Cleaning Rotary Valve Airlock, which makes the material handling more reliable with less sticking and clogging of hard-to-handle materials, while also offering a superior airlock performance.

- Made in America! All PMM Rotary Airlock Feeders, Rotary Valve Airlocks, and Heavy-Duty Screw Conveyors are proudly manufactured in America by hard-working Americans whose goal every day is to provide our customers with a superior airlock!