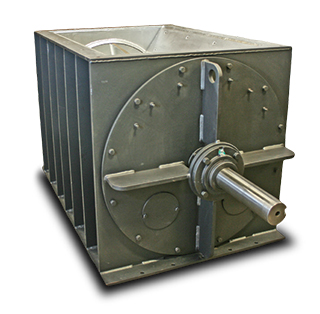

Heavy-Duty Rotary Valve Airlocks specifically for the demanding Coal-Fired Power Generation Industry

High-volume coal-fired power generation plants require Rotary Valve Airlocks capable of standing up to the abrasive qualities of coal, which can also deliver high volumes of lower-quality lignite coal just as effectively as higher-quality bituminous or subbituminous coal, while maintaining airlock functionality in a high-temperature environment. With a proven history of performance, PMM is the coal-fired power generation industry’s preferred airlock!

Perfect for Powdery & Granular Materials

Extreme Duty Rotary Valve Airlock

High-Volumes of Ash, Granular & Powdery Materials

Double Slope Rotary Airlock Feeder

Perfect for Low Quality Coal Applications

Self-Cleaning Rotary Valve Airlock

Wood, Organic and Alternative Fuel Materials

Rotary Airlock Feeder w/Knife

COAL-FIRED

POWER-GENERATION INDUSTRY

POWER-GENERATION INDUSTRY

Rotary Valve

Airlocks

Failure is not an options! Producing energy is demanding and very few rotary airlock manufacturers are up the task of successfully supporting this demanding industry! PMM manufactures extremely durable Rotary Valve Airlocks that are capable of meeting the specific needs of the Coal-Fired Power Generation industry.Rotary airlocks should NEVER be the weakest link in your emission control and DSI environmental systems. We understand the importance of precise, reliable injection of lime, trona or activated carbon to keep these systems performing as specified. Our solutions offer longer life, efficient waste-free use of materials.Move brown coal without sticky build-up! No matter where lignite coal is being introduced into the process, PMM has Rotary Valve Airlocks that can consistently and reliably feed brown coal while minimizing the potential for clogs.Working with super abrasive pet coke? No problem! We specialize in building Rotary Valve Airlocks for high-abrasive environments that last longer and requires far less maintenance.-

Rebuildable! Unlike common cast-iron airlocks, all PMM Rotary Valve Airlocks are rebuildable! This provides a greater ROI over the life of the product and significantly reduces CAPEX spend, along with overall maintenance costs.