Pulp Processing and Cogeneration Power Production requires the Highest Quality Rotary Airlock Feeders!

Welcome to Precision Machine & Manufacturing! We manufacture the heaviest duty Rotary Airlock Feeders and Screw Conveyors in the industry! Whether processing pulp, moving wood chips, or biomass alternative fuels for the cogeneration power plant, our Rotary Airlock Feeders are the most durable and have a long proven history to show for it! In addition, we manufacture heavy-duty application-specific Screw Conveyors, which are utilized throughout the industry including being used as digester screw conveyors, metering bin augers, and/or traversing screw conveyors to name a few. When it comes to solving common material-handling problems within the Pulp & Paper Industry, a call to Precision Machine & Manufacturing is the first and last step toward developing a true heavy-duty material-handling solution!

100% Made in America!

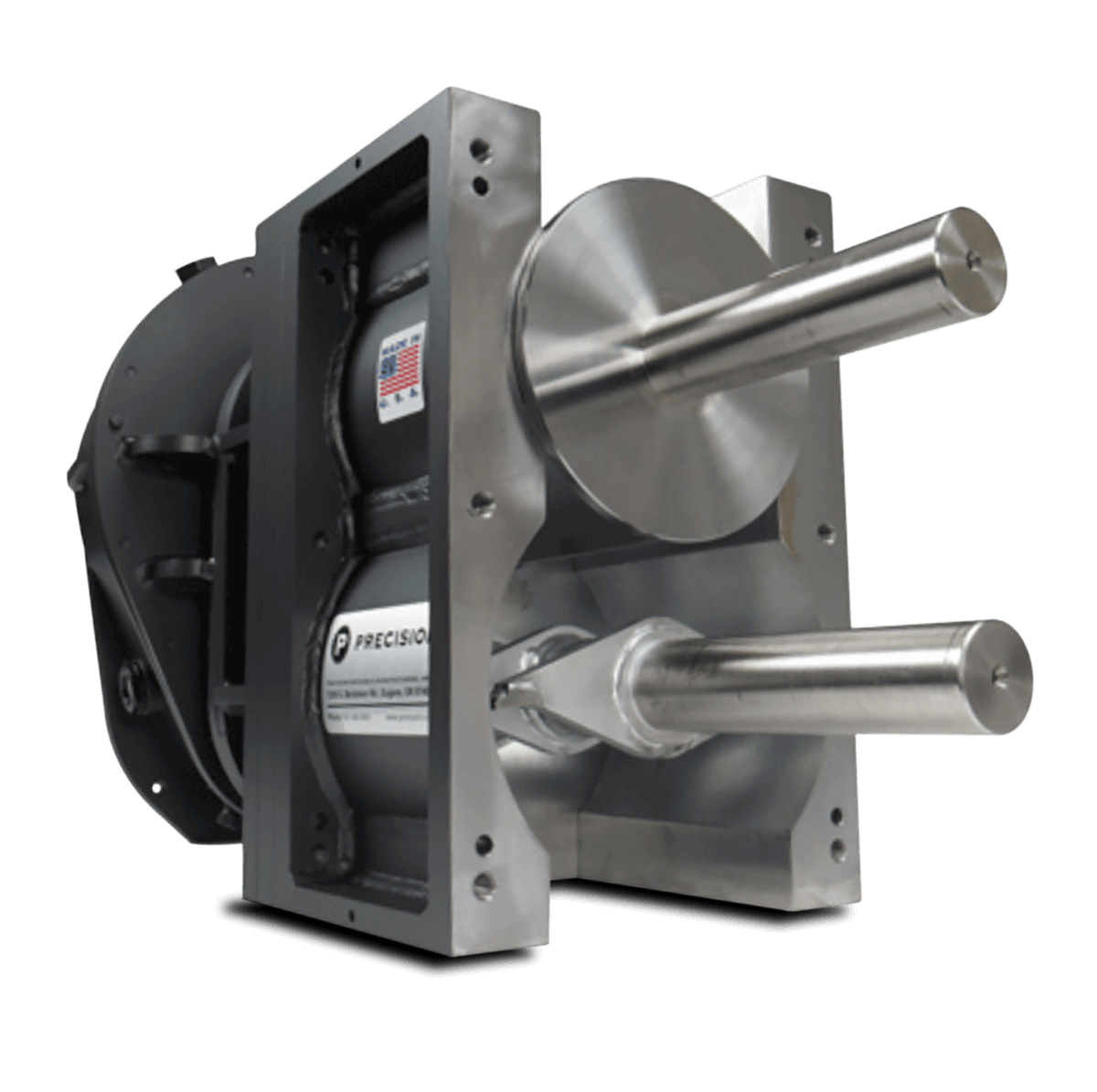

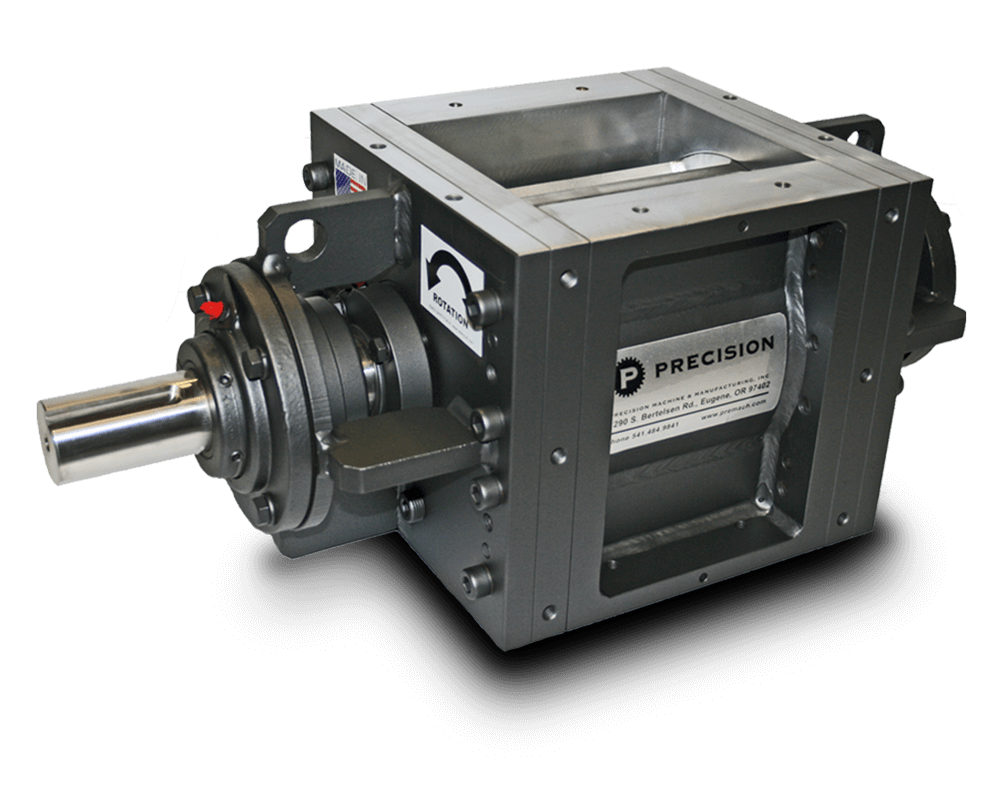

Rotary Airlock Feeder w/Knife

Double Slope Rotary Airlock Feeder

Self-Cleaning Rotary Valve

Extreme Duty Rotary Valve Airlock

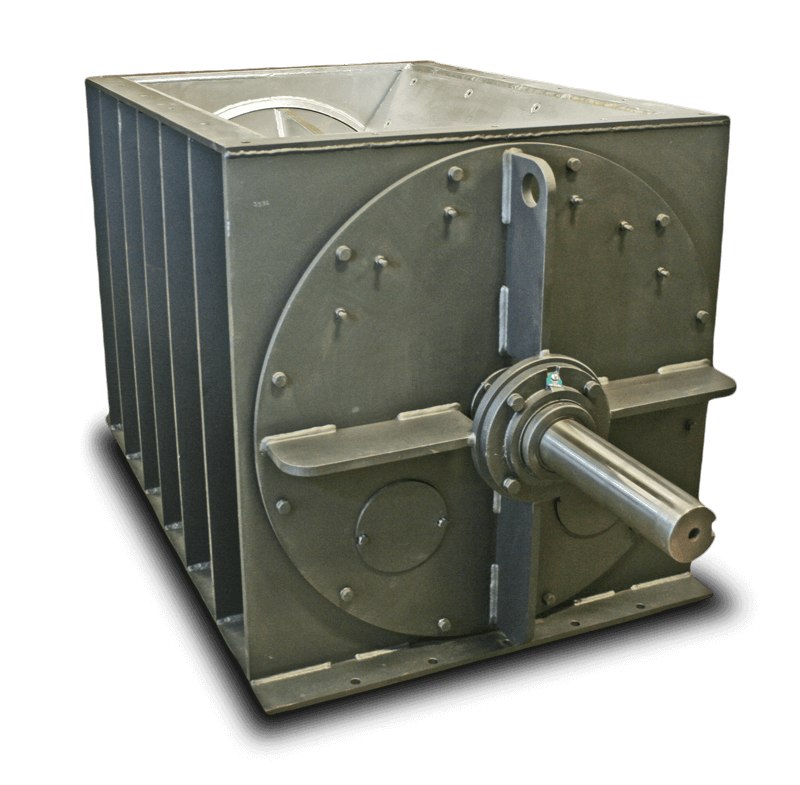

Manufacturing

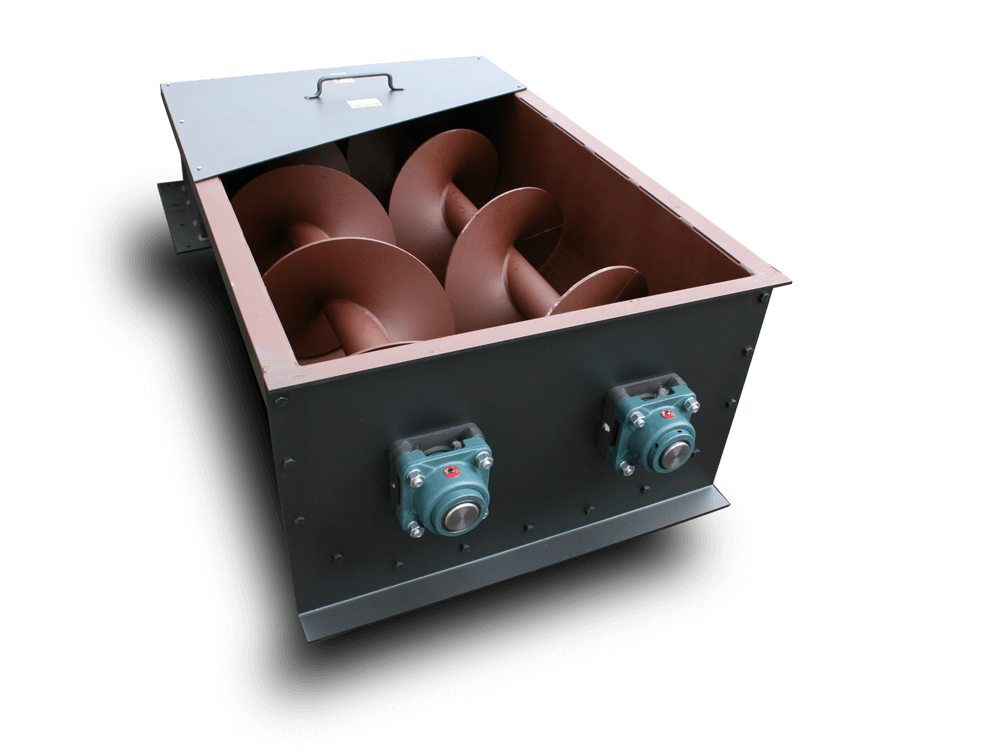

Rotary Airlocks & Heavy-Duty Augers

- Cutting through Wood Chips & Paper Pulp! Literally! PMM's Rotary Airlock Feeders are equipped with a hardened tool steel knife that easily shears irregular sized materials at the infeed so only commonly sized materials are discharged into the conveying system or the boiler itself.

- High-Temperature Rotary Airlocks! Every PMM Rotary Airlock Feeder is manufactured to meet the specific operational temperature of the environment where the airlock will be located as well as the temperature of the materials being conveyed. PMM's engineers precisely calculate the amount heat-related material expansion so the airlock functionality is maximized and the rotor can freely turn within the housing. Don't get stuck with a cast-iron airlock because the manufacturer did not account for heat expansion, call Precision Machine & Manufacturing!

- Biomass Power Generation requires quality airlocks! As the Biomass Power Generation Industry has grown so has material diversity. PMM's Rotary Airlock Feeders haven proven to be the only airlock that consistently stands up to rubber, carpet, wood, agriculture waste, and others types of organic matter. Abrasion-resistant materials and a hardended tool steel knife are what allows Precision Machine & Manufacturing's Rotary Airlock Feeder to deliver the required amount of material to the boiler, incinerator, and/or pneumatic conveyor with very little maintenance day in and day out.

- Made in America! All Rotary Airlock Feeders, Rotary Valve Airlocks, and Heavy-Duty Screw Conveyors are proudly manufactured in America by hard-working Americans whose goal every day is to provide our customers with a superior Rotary Airlock and/or Screw Conveyor.

- Rebuildable! All PMM material handling components are rebuildable! This provides a greater ROI over the life of the product and significantly reduces capital expenditures.

- Ash Handling Solutions! Regardless of the ash type whether it be bottom ash, fly ash, or another type of ash, Precision's Rotary Valve Airlock is the perfect Rotary Airlock to efficiently move this type of material. Each Rotary Valve is manufactued with abrasion-resistant materials and surface treated to push the hardness rating to nearly 60 Rockwell, making it the perfect airlock for any ash handling system.