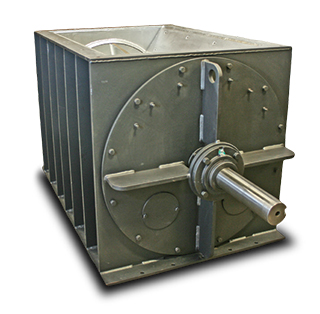

Super Heavy Duty Rotary Valve Airlocks for the Heavy Metal & Mineral Processing Industries

Precision Machine & Manufacturing specializes in manufacturing the heaviest duty Rotary Valve Airlocks in the material handling industry. Rotary airlocks built specifically for the processing of highly abrasive and corrosive minerals that are superior in every way when compared to standard cast-iron airlocks!

Always Made in the USA!

High-Volume Powdery, Granular, Ash Materials

Double Slope Rotary Feeder Airlock

Heavy-Duty & Perfect for Low Moisture Materials

Self-Cleaning Rotary Valve Airlock

METALS & MINERALS

INDUSTRY

INDUSTRY

Rotary Valve

Airlocks

Minerals are simply hard on equipment! We understand the difficulty with deploying components that can stand up to the abrasiveness or corrosiveness of the material being conveyed. It is for this reason that we manufacture all Rotary Valve Airlocks from a special U.S. sourced through-hardened abrasion-resistant steel alloy and surface treat the material, which pushes the overall hardness to near 60 Rockwell. If our airlocks don't stand up, nothing will!Failure is not an option! You are counting on us to deliver, and our guarantee is that we will!Rebuild vs. Replace! All PMM Rotary Valve Airlocks are rebuildable! This increases the return on investment over the life of the product and improves overall up-time as wear items are replaced during a schedule outtage versus replacing an entire airlock due to component failure in between outages.Size Matters! All deployed Rotary Valve Airlocks are precisely sized to meet the throughput requirements of the material handling system. There is no guessing here, only perfection!Eliminate constant stoppages & maintenance headaches! There is no reason to be constantly dealing with work stoppages because an airlock needs to be cleaned out. Deploy one of PMM"s Self-Cleaning Rotary Valve Airlocks and elminate constant downtime and maintenace headaches!Single Source Supplier of all your rotary valve airlocks. Simplify spare and critical parts by utilizing PMM as your preferred supplier for material handling components.Precise airlock functionality! PMM's proprietary manufacturing process allows for the tightest possible rotor to housing clearances, while still providing industry leading metering capabilities. In addition, because the airlock is made from abrasion-resistant materials, the airlock functionality is maintained far longer than a cast-iron airlock can provide.