Heavy Duty Rotary Airlock Feeders for the Cement Manufacturing Industry

Precision Machine & Manufacturing is the Cement Manufacturing Industry’s preferred Rotary Valve Airlock manufacturer! PMM’s robust, high-volume Raw Mill Rotary Airlock Feeders are commonly used for conveying limestone into the raw mill delivery system and like all of PMM’s Airlocks are equipped with the industry’s tightest rotor to housing clearances, which maximizes the airlock functionality. In addition, PMM’s Heavy-Duty Rotary Airlocks can be found in a variety of material handling applications throughout the plant’s operation including the cogeneration power plant moving lignite coal, rubber, and/or other alternative fuels, under baghouses, blending cyclones, and within dust collection systems.

Every component is 100% Made in the USA!

Rotary Airlock Feeder w/Knife

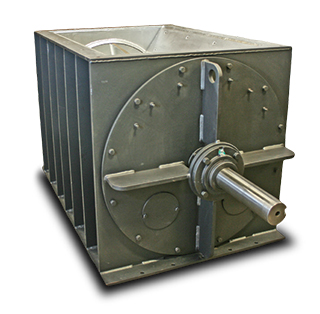

Extreme Duty Rotary Valve Airlock

Self-Cleaning Rotary Valve Airlock

MANUFACTURING

Rotary Airlock Feeders

- Eliminate Triple Flap Gate Valves! Triple flap gate valves are maintenance heavy, innefficent due the amount of air allowed to pass through, and expensive to operate in terms of the constant upkeep and downtime of the raw mill material handling process. Replace these components with a Raw Mill Rotary Airlock Feeder from Precision Machine & Manufacturing and move those triple flap gate systems to the scrap yard where they belong!

- Replace cheaply made cast-iron airlocks! Cheap cast-iron airlocks were never made to hold up to the abrasive materials moving through a Cement Manufacturing plant. This is why most newly installed cast-iron airlocks will begin to show their true colors within 6-months from the date of installation, which is when the inefficiency starts and the daily maintenance cleanouts begin. PMM's Rotary Valve Airlocks will outlive cheap cast-iron airlocks 3 to 1!!

- Don't replace bad with bad! When the original conveying and/or material handling system was designed and installed by companies like "Schen..," they did not source the highest quality product for the system because it would drive up the overall cost. Instead, marginal components were chosen that technically checked off the boxes, but were not the best option. As you look at replacing those original airlocks, choose a Rotary Airlock that was manufactured specifically for the Cement Manufacturing Industry.

- A Rotary Valve Airlock for all occations! There are many different material handling systems operating throughout a cement plant. PMM has a Rotary Valve Airlock for all of them! PMM's Rotary Feeder is perfect for the alternative fuels cogeneration conveying line, and the Self-Cleaning Rotary Valve is the optimum solution to replace maintenance heavy Raymond coal mills in the lignite coal line. The Extreme-Duty Rotary Valve is perfect for the abrasiveness and material particle size in the dust collection system. Bottom line, PMM has an airlock that we built for your application!

- Rebuildable! All PMM Rotary Airlocks are rebuildable! This provides a greater ROI over the life of the product while significantly reducing CAPEX purchases. In addition, this opens the door for PMM to deploy an "exchange" program, which ensures the plants airlocks are always functioning at peak performance.