Statement of Compliance – NFPA 69 & 85 Standards

Customer & Application Specific

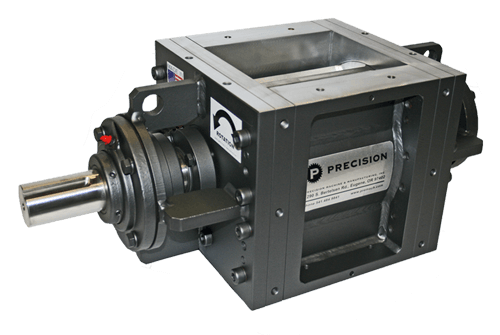

When the customer and/or the application requires an NFPA compliant Rotary Valve Airlock, Precision Machine & Manufacturing is the only manufacturer that builds a true NFPA compliant Rotary Valve Airlock that meets the relevant sections of the NFPA 69 Standard on Explosion Prevention Systems and the NFPA 85 Boiler and Combustion Systems Hazards Code (2019 version).

PMM’s Rotary Valve Airlocks are the perfect addition to any material handling system when and where safety is of the utmost importance!

These standards provide important guidelines and regulations for the safe operation of Close-Clearance Rotary Valves operating within industrial manufacturing material handling systems.

NFPA Frequently Asked Questions

Standard

12.2.4.2

Relevant Section: Chapter 12 Deflagration Control by Passive Isolation Rotary Valve Design Criteria

PMM NFPA Compliance: When customer specified, PMM Rotary Valves are upgraded to comply with the “close clearance valve” specifications as outlined in NFPA 69, subsection: 12.2.4.5

Standard

12.2.4.3.1

The valve body and rotor shall have sufficient strength to withstand the maximum anticipated explosion pressure.

PMM NFPA Compliance: PMM Rotary Valves have a design pressure of 14.9 psi.

Standard

12.2.4.3.3

The valve pressure resistance shall be verified or tested by a knowledgeable test authority.

PMM NFPA Compliance: PMM Rotary Valves have been tested by an independent authority and tested up to 50 psi, with no structure deflection or deformation.

Standard

12.2.4.3.4

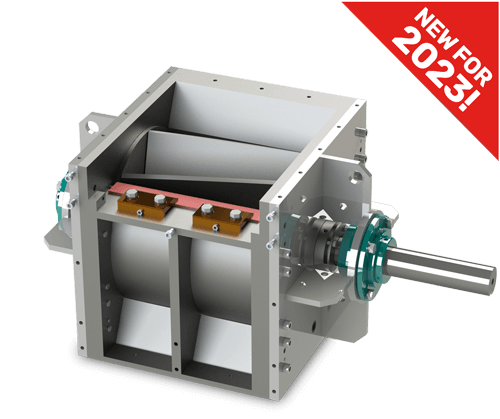

There shall be at least six vanes on the rotary, diametrically opposed.

PMM NFPA Compliance: As a standard all PMM Rotary Valves have at least six vanes, which are diametrically opposed.

Standard

12.2.4.3.5

At least two vanes on each side of the valve housing shall be in a position of minimum clearance at all times.

PMM NFPA Compliance: When customer specified, PMM Rotary Valves are upgraded to ensure that at least two of the valve’s vanes are in contact with each side of the barrel (housing), at all times.

Standard

12.2.4.3.6

The valve shall have metal body and vanes unless it is shown by best data that nonmetallic or composite materials prevent flame passage.

PMM NFPA Compliance: As a standard all PMM Rotary Valves contain a metal body and rotor. Each is manufactured from a specialty through hardened, 500 Brinell abrasion-resistant steel alloy, which is ion-nitride surface treated to obtain a hardness rating of 62-64 Rockwell.

Standard

12.2.4.3.7

Rotary valve bearings shall be mounted externally.

PMM NFPA Compliance: As a standard all PMM Rotary Valves are equipped with heavy-duty, outboard tapered roller bearings.

Standard

12.2.4.5.1

Close-clearance rotary valves shall be designed with a clearance between the vane and the valve body that is less than or equal to 0.2 mm (0.008 in.)

PMM NFPA Compliance: When customer specified, PMM Rotary Valves are upgraded to ensure the clearance between the vane and valve body is less than or equal to 0.2 mm (0.008 in.).

-SIZING INFORMATION: All PMM Rotary Valves are sized according to the material being handled and the environmental temperature where the rotary valve will be operating.

-Depending upon the operational temperature, the clearances at startup might be slightly larger/smaller to allow for the precise amount of rotor swelling/shrinking to achieve the rotor to housing clearance requirement.

Standard

12.2.4.5.2

The clearance between vane and valve body shall be small enough to prevent the passage of flame between the rotor and the valve housing.

PMM NFPA Compliance: PMM Rotary Valves are manufactured per a specialized proprietary process, which allows for the tightest possible clearance between the rotor and housing, while still allowing the rotor to turn.

-Please note: No rotary valve is 100% air-tight, and although PMM’s industry leading rotary valves do posses the tightest possible rotor to housing clearance among all rotary valve manufacturers, minimal space is necessary to enable turning of the rotor.

Standard

12.2.4.5.3

Actual clearances of such rotary valves shall be measured before installation and monitored using a predictive maintenance program such that the design clearance is not exceeded due to wear.

PMM NFPA Compliance: All PMM Rotary Valves are shipped from the factory with the precise amount of clearance to meet the operational temperature of the environment. When customer specified, PMM Rotary Valves are upgraded to ensure compliance with the required NFPA specified rotor to housing clearances.

-Please note: It is the responsibility of the end-user/operating company to ensure deployment of a comprehensive preventive maintenance program, which occurs at specific intervals, preferably every 3-months at a minimum, includes measuring and monitoring rotor to housing clearances, and is capable of making adjustments and/or replacing worn components when necessary.

-Please note: When the rotary valve is received, the actual clearances may be slightly larger/smaller. This is to allow for expansion or shrinkage do to the environmental temperatures where the rotary valve will be operating.

Standard

12.2.4.6

Rotary Valve Application Limits: Rotary valves shall not be permitted to be used as an isolation device for systems handling hybrid mixtures or gases.

PMM NFPA Compliance: WE AGREE! Here at PMM, we do not endorse the use of PMM Rotary Valves as an isolation device in these types of applications and under any circumstance.

ANNEX A

A.12.2.4.5

Testing has shown that rotary valves can be effective in isolating explosion propagation if the following conditions are in place:

(1) There are three vanes on each side of the valve that are diametrically opposed.

(2) A close tolerance is maintained between the vanes and the valve body, less than or equal to .008”.

(3) Two vanes per side are always in contact with the housing

(4) The vanes or tips are made out of metal and have a thickness of at least .12” PMM NFPA Compliance: When customer specified, PMM Rotary Valves are upgraded to meet the specifications at outlined.

Standard

9.1.3

Covers pulverized fuel systems designed to reduce fuel to a size such that at least 50% will pass through 200-mesh (74 micron) sieve.

PMM NFPA Compliance: When customer specified, PMM Rotary Valves are upgraded to be manufactured per NFPA 69 standards, which is applicable in various NFPA 85 codes referencing boiler and stoker applications.

Standard

9.3.6

Where used as a means for deflagration isolation, rotary valves (material chokes) shall be installed and maintained in accordance with NFPA 69.

When customer specified, PMM Rotary Valves are upgraded to be manufactured per NFPA 69 standards.

Standard

9.4.3.2.2

All components of the raw fuel feeder system shall be designed to withstand an internal deflagration without rupture.

PMM NFPA Compliance: PMM Rotary Valves have been tested by an independent test authority up to 50 psi, with no structure deflection or deformation.

Standard

9.4.3.2.7.1

All valves in the raw fuel feeder system shall have construction capable of withstanding pressures as defined in 9.4.3.2.2.

PMM NFPA Compliance: PMM Rotary Valves have a design pressure of 14.9 psi.

Standard

9.7.3.3.2.1

Special dust tight valves shall be installed at each fuel outlet of the pulverized fuel bin, the fuel discharge outlet, and each fuel outlet of the pulverized fuel distributors.

PMM Rotary Valves have a long and proven history of operating in dust collection and dust prevention applications.

Why Precisions?

sed quia non incidunt lores ta porro ame. -Steve Wison, Monarch Cement